Introduction:

One of the single most important aspect in achieving successful pipe leak repair is the surface preparation of the affected pipe section to be repaired. For repairs to carbon steel pipe it is normally possible to achieve durable adhesion strength through means of mechanical abrasion being the only method of surface preparation. It is important that the nature of the abrasion technique is fully specified in accordance to standards e.g. blast cleaned to Swedish Standard SA3.

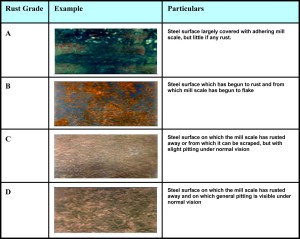

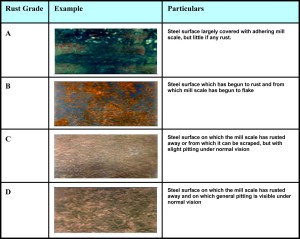

Different Grades of Rust:

Surface Contaminants:

Residues of oil, grease, marking inks, cutting oils etc. after fabrication operations will seriously affect the adhesion of applied coatings and must be removed. It is erroneous to think that subsequent cleaning operations will remove such contaminants and it is bad practice to permit them to remain on the surface. Failure to remove these contaminants before blast cleaning results in them being distributed over the steel surface and contaminating the abrasive. Suitable organic solvents, emulsion degreasing agents or equivalents should be applied to remove contaminants in preparation for subsequent descaling treatments. Further guidance can be obtained from BS 7773 ‘Code of Practice for Cleaning and Preparation of Metal Surfaces.

Surface Preparation Methods

Surface preparation can be performed via abrasive blast cleaning or by power and hand tools.By far the most significant and important method used for the thorough cleaning of mill-scaled and rusted surfaces is abrasive blast cleaning. This method involves mechanical cleaning by the continuous impact of abrasive particles at high velocities on to the steel surface either in a jet stream of compressed air or by centrifugal impellers. The latter method requires large stationary equipment fitted with radial bladed wheels onto which the abrasive is fed. As the wheels revolve at high speed, the abrasive is thrown onto the steel surface, the force of impact being determined by the size of the wheels and their radial velocity. Modern facilities of this type use several wheels, typically 4 to 8, configured to treat all the surfaces of the steel being cleaned. The abrasives are recycled with separator screens to remove fine particles. This process can be 100% efficient in the removal of mill scale and rust.

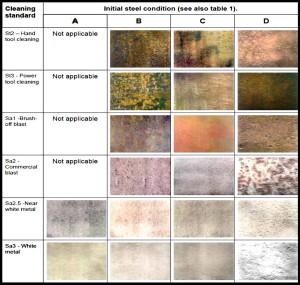

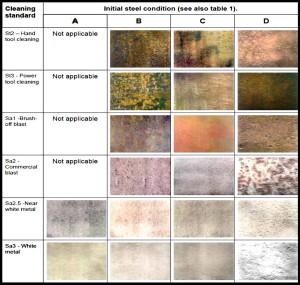

When applying abrasive blast cleaning, the standard grades of cleanliness for are:Sa1 Light blast cleaning. Sa2 Thorough blast cleaning. Sa2.5 Very thorough blast cleaning. Sa 3 Blast cleaning to visually clean steel Surface cleaning by hand tools such as scrapers and wire brushes is relatively ineffective in removing mill scale or adherent rust. Power tools offer a slight improvement over manual methods and these methods can be approximately 30% to 50% effective but are not usually utilised for new steel work fabrications.

Hand Tool cleaning (St Grade)• Removes mill scale, rust etc., from steel • Cleaned using hand wire brushing, sanding, scrapping and chipping • Mostly used when power tool cannot be used • Feasible for localised/ small jobs • St 2-B, C or D grades are typically employed

Power Tool Cleaning (St Grade)• Removes loosely adhering mill scale & rust • Does not remove tightly adhering mill scale & rust • Rotary wire brushes , sanding disc and needle guns are the tools employed • Relevant prep grades are St2-B, C or D and St3-B, C or D

Blast Cleaning

Blast Cleaning• Removes mill scale, rust etc., from steel • Abrasive jet of particles in a compresses air stream impinges on the surface for cleaning • Imparts a surface roughness to the steel • Widely used method for complete surface preparation in the repair industry • Sa 1, Sa 2, 2.5 or Sa 3 are typically employed

Pictorial examples of Surface Preparation

Once the pipe surface has been prepared to the required standards and the surface profile has met the required roughness, subsequently the repair works should commenced within 4 hours.

Blast Cleaning• Removes mill scale, rust etc., from steel • Abrasive jet of particles in a compresses air stream impinges on the surface for cleaning • Imparts a surface roughness to the steel • Widely used method for complete surface preparation in the repair industry • Sa 1, Sa 2, 2.5 or Sa 3 are typically employed

Blast Cleaning• Removes mill scale, rust etc., from steel • Abrasive jet of particles in a compresses air stream impinges on the surface for cleaning • Imparts a surface roughness to the steel • Widely used method for complete surface preparation in the repair industry • Sa 1, Sa 2, 2.5 or Sa 3 are typically employed

Once the pipe surface has been prepared to the required standards and the surface profile has met the required roughness, subsequently the repair works should commenced within 4 hours.

Once the pipe surface has been prepared to the required standards and the surface profile has met the required roughness, subsequently the repair works should commenced within 4 hours.