ACTIVE LEAK REPAIR KIT

WRAP SEAL ULTRA QUICK REPAIR KIT FOR ACTIVE PIPE LEAKS

FEATURES:

- Repairs under active leak up to 150 psi (11 kg/cm2) pressure

- No shutdown required

- Works on any metal or non-metal pipes

- Applicable to pipes up to 18″ (457 mm) diameter

- Repairs leak in 15 minutes

- Withstand pressure up to 500 psi (35 kg/cm2)

- Withstand temperature up to 200 °C (392 °F)

- Safe for drinking water and resistant to most chemicals

- Ideal for pipeline reinforcement

APPLICABLE MATERIAL:

- Steel

- Copper

- Aluminium

- Galvanized steel

- PVC

- CPVC

- Stainless steel

- Polyethylene

- Polypropylene

- Cast-iron

- Concrete

- FRP/GRE

CHEMICAL RESISTANCE:

- Oil

- Water (drinking water, wastewater, steam)

- Solvents (acetone, toluene, MEK, ethyl alcohol)

- Mild acids (hydrochloric acid, sulfuric acid) and alkalis

- Chemical (ethylene glycol, xylenes, ammonia)

- Hydrocarbons

- Bases

- Slurries

- Fuels (petroleum, diesels, gasoline)

- Gases (LNG, LPG)

- Organic salts

WORKING TIME (FIBERGLASS TAPE):

1 minute at 30 °C (86 °F)CURING TIME:

- 30 minutes at 30 °C (86 °F)

- Heat may be applied to decrease curing time

- Unopened foil pouch may be immerse in cold water prior to repair to add working and curing time.

APPLICATION:

- Pipe repairs

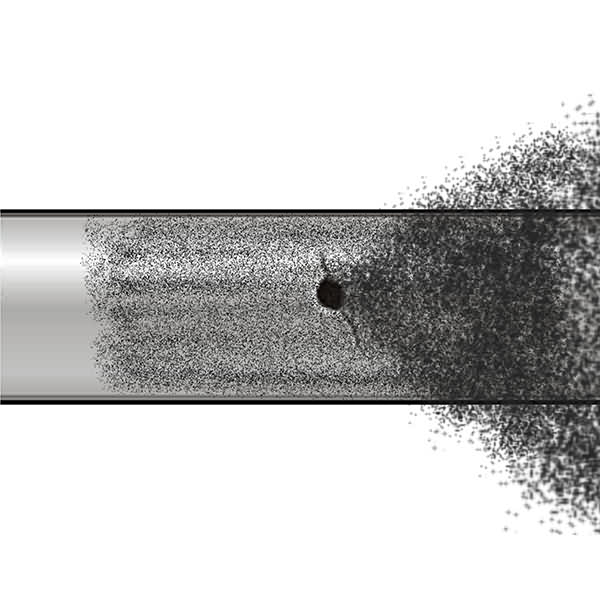

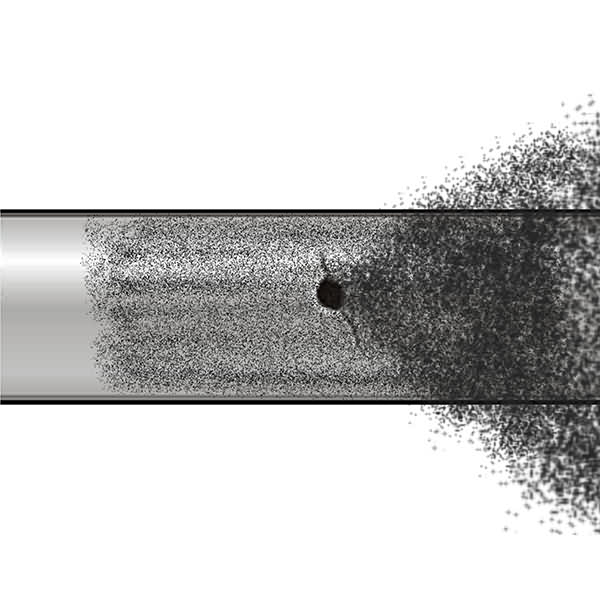

- Active pipe leaks

- Sealing joints

- Hazardous material spill control

- Reinforce thinning walls

- Repairs in hard to reach areas

- Underwater repairs

OPERATING TEMPERATURE:

-50 °C (-58 °F) to 200 °C (392 °F)OPERATING PRESSURE:

- Recommended for pressure up to 500 psi (35 kg/cm2)

- (Result vary depending on pipe size, type of pipe, hole size, pipe content and method of application)

APPLICABLE INDUSTRIES:

Building & Facilities

Building & Facilities Electronics

Electronics Industrial Processing

Industrial Processing Irrigation

Irrigation Oil & Gas

Oil & Gas Chemical

Chemical Manufacturing Plants

Manufacturing Plants Marine

Marine Military

Military Offshore

Offshore Food Processing

Food Processing Petrochemical

Petrochemical Pharmaceutical

Pharmaceutical Power Generation

Power Generation Pulp & Paper

Pulp & Paper Wastewater

Wastewater Water Distribution

Water DistributionTECHNICAL DATA:

| Tensile strength | : | 3920 psi (276 kg/cm2) |

| Bond strength | : | 230 psi (16 kg/cm2) |

| Tensile elongation | : | 1.2 % ± 0.7 % |

| Compression strength | : | 13750 ± 530 psi (967 ± 37 kg/cm2) |

| Yield strength | : | 2260 psi (159 kg/cm2) |

| Cured hardness | : | 82 Shore D |

| Dielectric strength | : | 400 Volts/mil |

| Pipe size | Number of rolls / size required | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| ½” (15mm) | 1 A | 1 A | 1 A |

| ¾” (20mm) | 1 A | 1 A | 1 A |

| 1″ (25mm) | 1 A | 1 A | 2 A |

| 1¼” (32mm) | 1 A | 2 A | 3 A |

| 1½” (40mm) | 2 A | 2 A | 1 B |

| 2″ (50mm) | 1 B | 1 B | 1 B |

| 2½” (65mm) | 1 B | 1 B | 2 C |

| 3″ (80mm) | 1 B | 2 C | 2 C |

| 4″ (100mm) | 1 B | 2 C | 3 C |

| Pipe size | Number of rolls / size required | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| 5″ (125mm) | 2 C | 2 C | 3 C |

| 6″ (150mm) | 2 C | 2 C | 4 C |

| 8″ (200mm) | 2 C | 3 C | 5 C |

| 10″ (250mm) | 3 C | 4 C | 6 C |

| 12″ (300mm) | 4 C | 5 C | 8 C |

| 14″ (350mm) | 4 C | 6 C | 8 C |

| 16″ (400mm) | 5 C | 7 C | 9 C |

| 18″ (450mm) | 5 C | 8 C | 9 C |

| > 18″ (450mm) | Contact SealXpert for recommendations | ||

| Roll size | A (2″ x 6′) (50mm x 1.8m) | B (2″ x 12′) (50mm x 3.6m) | B (3″ x 9′) (75mm x 2.7m) | C (4″ x 12′) (100mm x 3.6m) |

WRAP SEAL ULTRA ACTIVE LEAK REPAIR PROCEDURE:

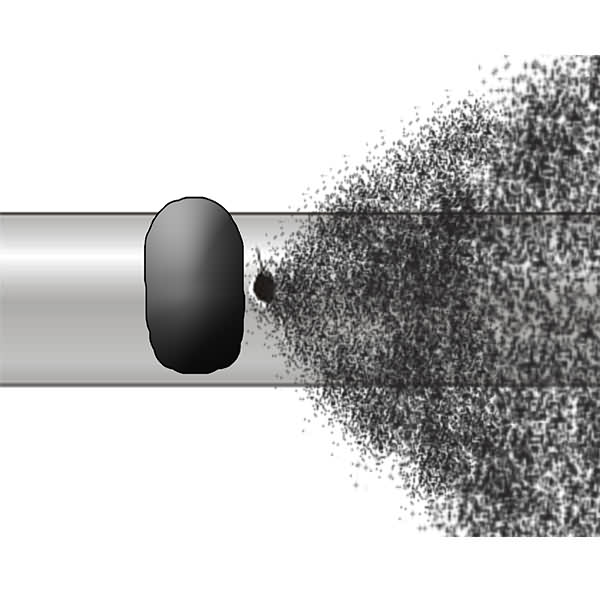

1 Minimize the flow rate and reduce system pressure

Minimize the flow rate and reduce system pressure

Minimize the flow rate and reduce system pressure

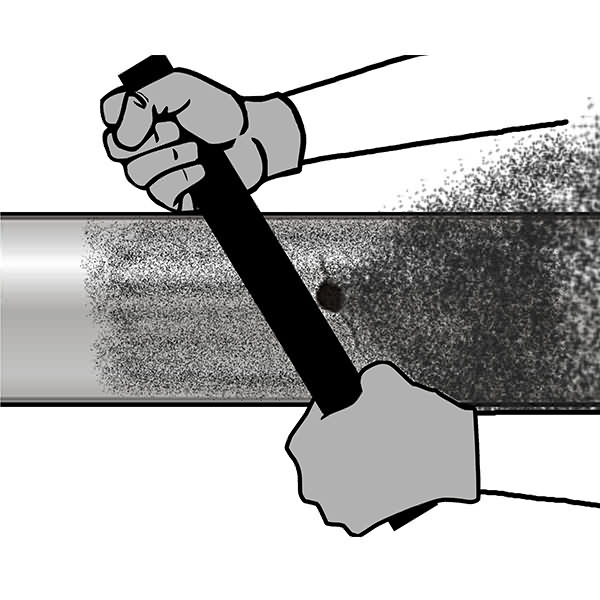

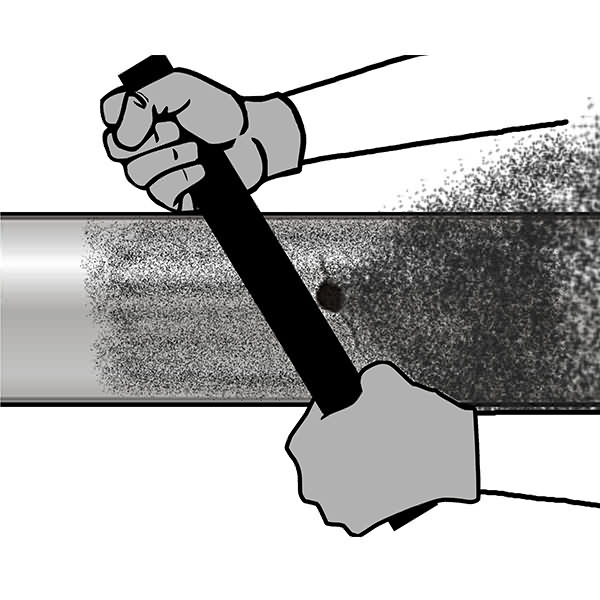

Minimize the flow rate and reduce system pressure2 Roughen the area to be repaired

Roughen the area to be repaired

Roughen the area to be repaired

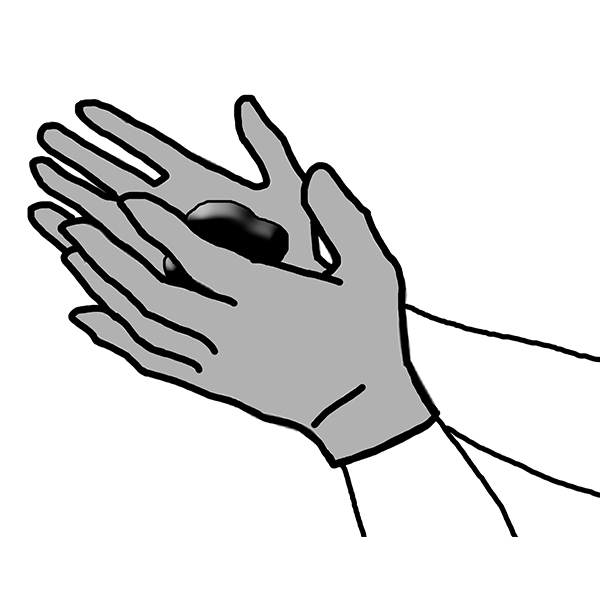

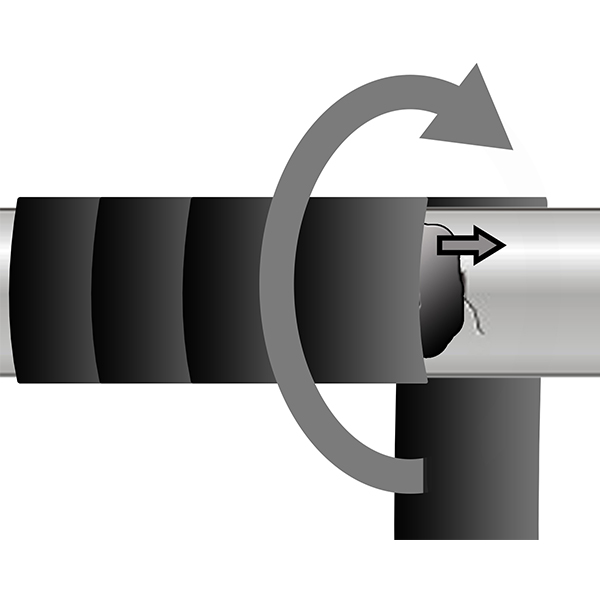

Roughen the area to be repaired3 Knead the Seal Stic

Knead the Seal Stic

Knead the Seal Stic

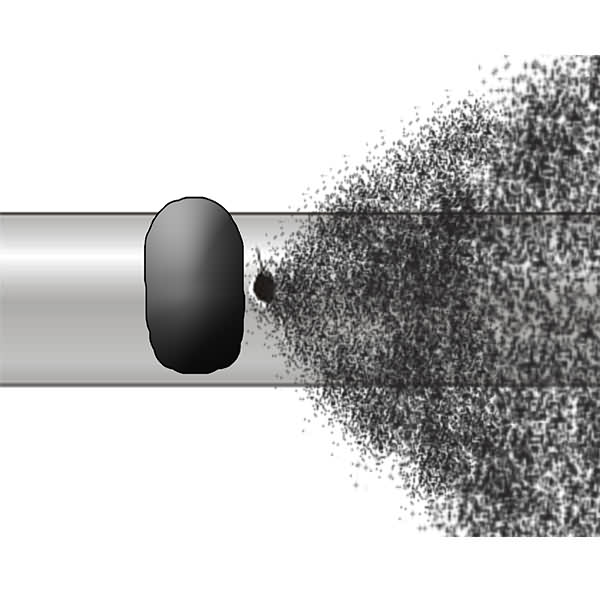

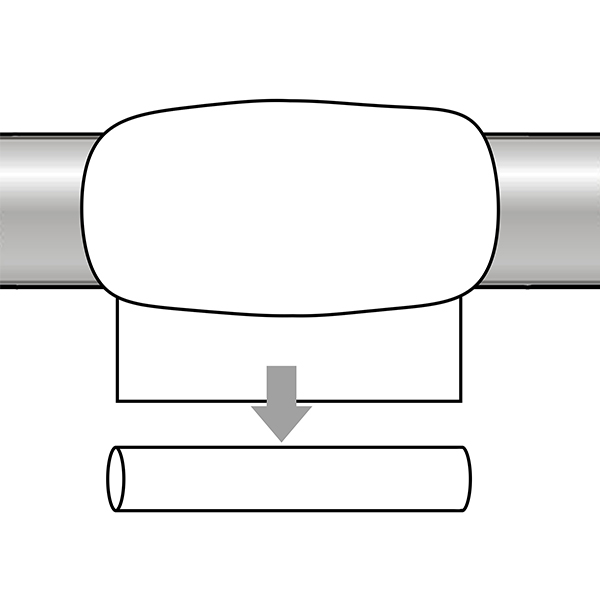

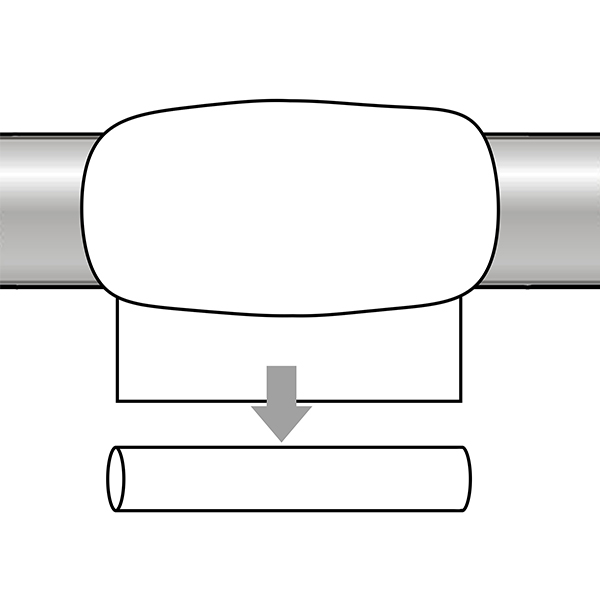

Knead the Seal Stic4 Place the Seal Stic away from the leak location

Place the Seal Stic away from the leak location

Place the Seal Stic away from the leak location

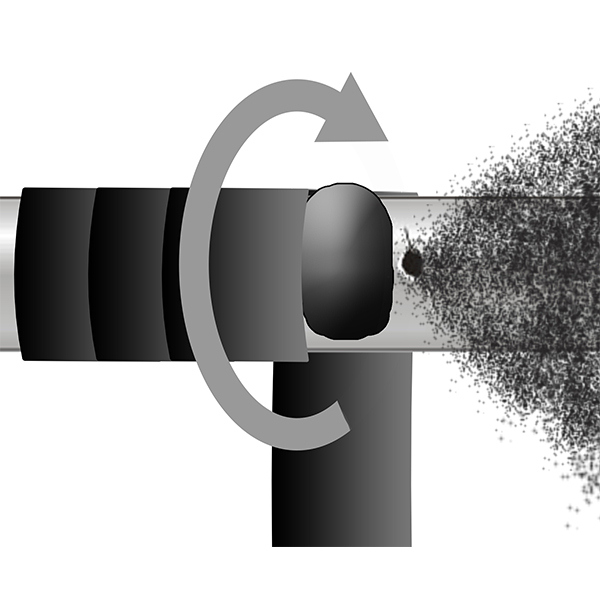

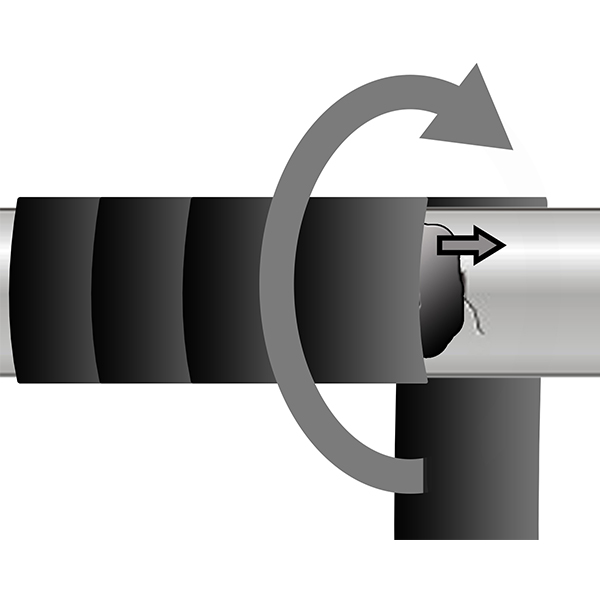

Place the Seal Stic away from the leak location5 Start wrapping the SealXpert Ultra Sealing Tape a few distances away from the leak location

Start wrapping the SealXpert Ultra Sealing Tape a few distances away from the leak location

Start wrapping the SealXpert Ultra Sealing Tape a few distances away from the leak location

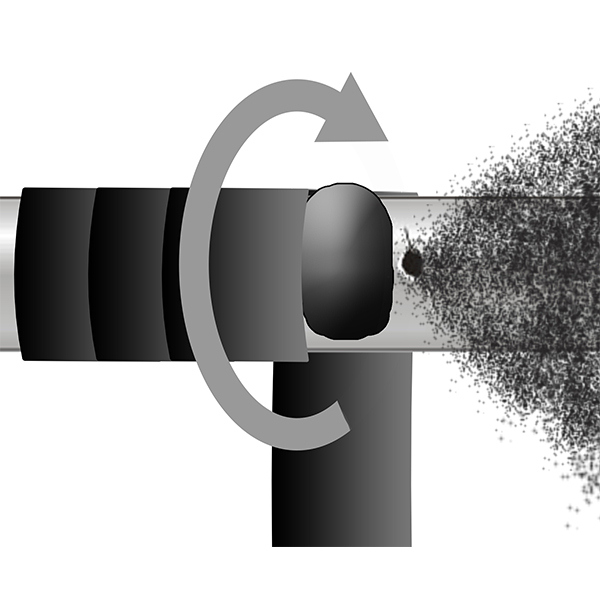

Start wrapping the SealXpert Ultra Sealing Tape a few distances away from the leak location6 Continue to wrap SealXpert Ultra Sealing Tape onto pipe while pushing the Seal Stic onto leak location

Continue to wrap SealXpert Ultra Sealing Tape onto pipe while pushing the Seal Stic onto leak location

Continue to wrap SealXpert Ultra Sealing Tape onto pipe while pushing the Seal Stic onto leak location

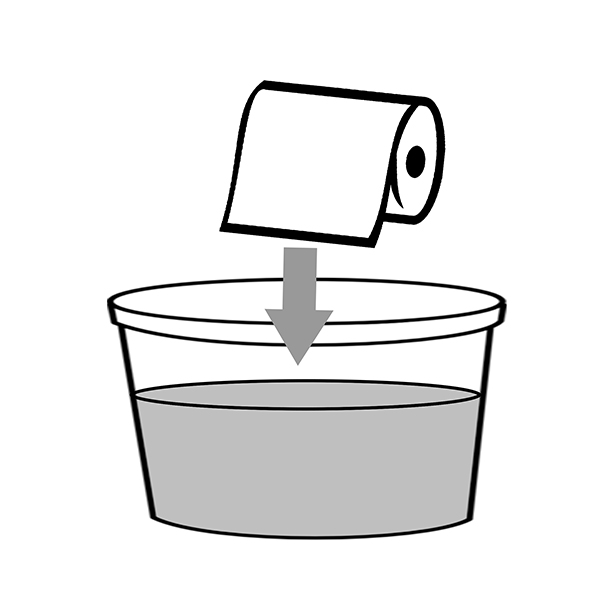

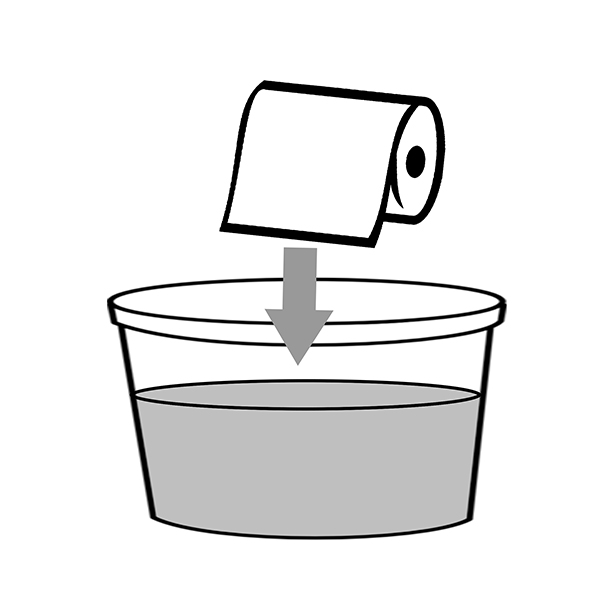

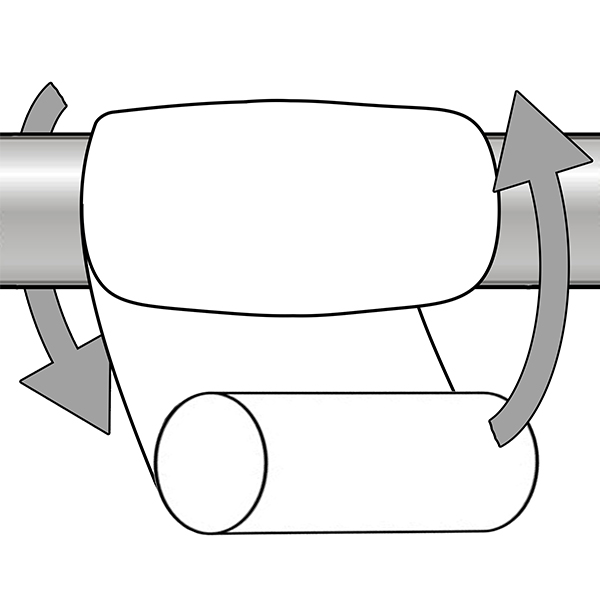

Continue to wrap SealXpert Ultra Sealing Tape onto pipe while pushing the Seal Stic onto leak location7 Immerse Wrap Seal Fiberglass Tape into water

Immerse Wrap Seal Fiberglass Tape into water

Immerse Wrap Seal Fiberglass Tape into water

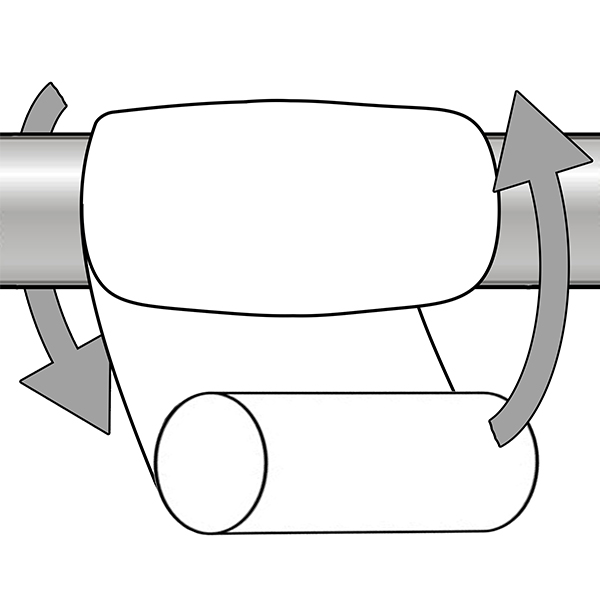

Immerse Wrap Seal Fiberglass Tape into water8 Wrap the Wrap Seal Fiberglass Tape above the repair tape as tightly and evenly as possible, using the entire roll

Wrap the Wrap Seal Fiberglass Tape above the repair tape as tightly and evenly as possible, using the entire roll

Wrap the Wrap Seal Fiberglass Tape above the repair tape as tightly and evenly as possible, using the entire roll

Wrap the Wrap Seal Fiberglass Tape above the repair tape as tightly and evenly as possible, using the entire roll9 Discard the plastic tube at the end of the roll

Discard the plastic tube at the end of the roll

Discard the plastic tube at the end of the roll

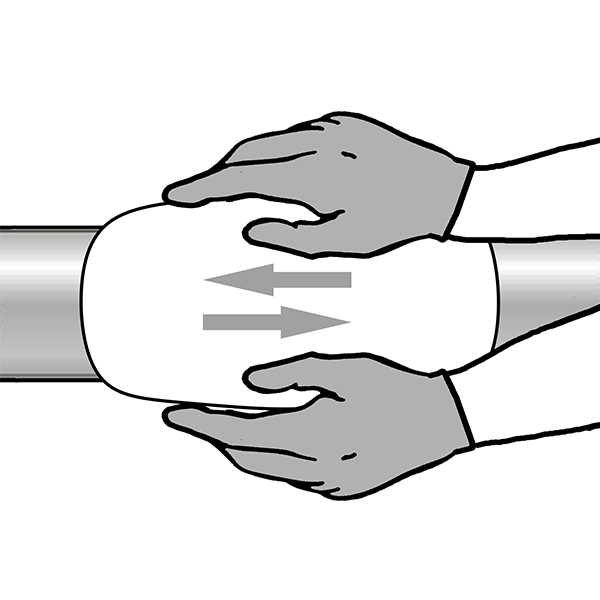

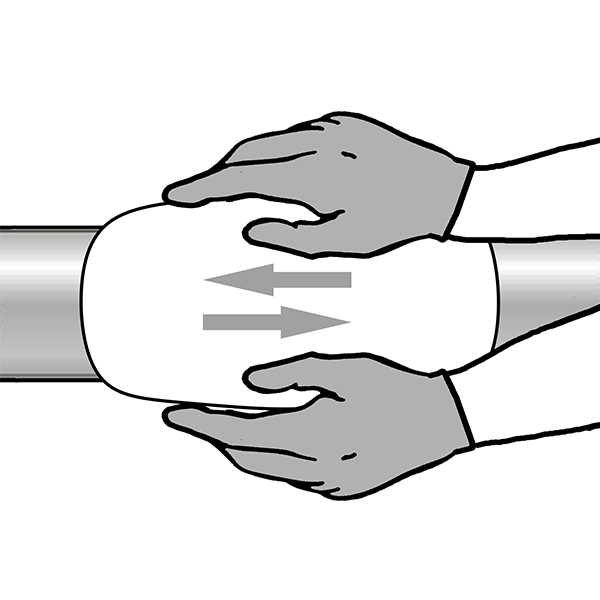

Discard the plastic tube at the end of the roll10 Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearanceWRAP SEAL ULTRA QUICK REPAIR KIT FOR ACTIVE PIPE LEAKS

PACKAGE:

- 1 roll of Wrap Seal Fiberglass Tape

- 2″ x 6′ (50 mm x 1.8 m)

- 2″ x 12′ (50 mm x 3.6 m)

- 3″ x 9′ (75 mm x 2.7 m)

- 4″ x 12′ (100 mm x 3.6 m)

- 1 roll of SealXpert Ultra Sealing Tape

- 1″ x 16′ (25 mm x 5 m)

- 1″ x 16′ (25 mm x 5 m)

- 1¼” x 16′ (32 mm x 5 m)

- 2″ x 16′ (50 mm x 5 m)

- 1 unit of Seal Stic Quick Cure Epoxy

- 1 pair of latex gloves

- Operating instruction