Our Blog

Types of Breakdown of Corrosion Protection Coatings

Introduction Anti-corrosion coating breakdown is covered here from a physical viewpoint. BLISTERING VIA OSMOSIS Blistering is usually caused by the presence of ionic contamination or water soluble species at the interface between the anti-corrosion coating and the steel. Water is drawn from the environment through the anti-corrosion coating from an area of low ionic concentration […] Read More

Notes for a Successful Composite Repair

Introduction In order to determine a suitable composite repair solution, the operator should provide the following information: • Pipeline design and operating pressure; • Pipeline design and operating temperature; • Pipeline medium; • Required lifetime of the repair. DOCUMENTATION AND DATA REQUIREMENTS FOR PIPEWORK REPAIRS DOCUMENTATION REQUIREMENT FOR VARIOUS OPERATING CONDITIONS (1) BASIC MATERIAL […] Read More

Factors Affecting Lifetime of Corrosion Protection Coatings

Introduction For the reasons described in the previous chapter, corrosion requires a ready supply of oxygenated, conducting sea water and somewhere for the corrosion products to form. Anti-corrosion coatings work by firstly excluding water, ions and oxygen from reaching the steel and secondly, by preventing the products of the corrosion reaction from escaping from the […] Read More

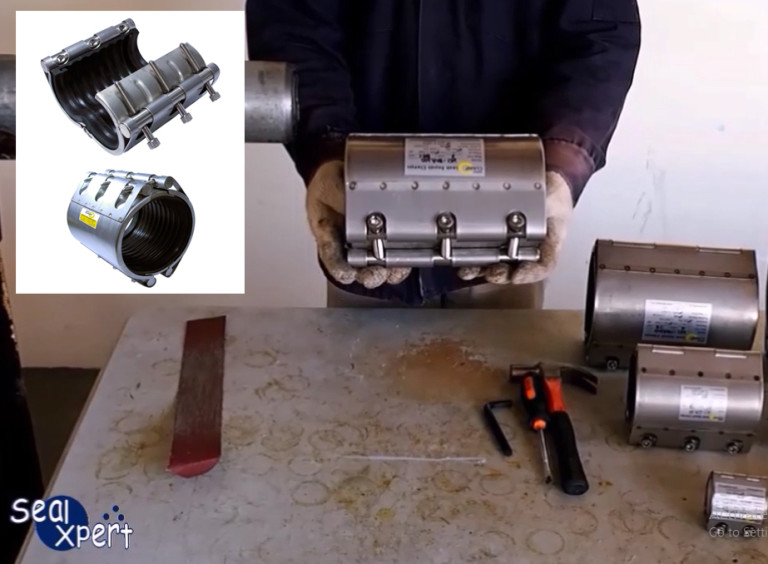

Different Type of Pipe Leak Repair Clamps and their Effectiveness

Introduction One of the fundamental aspects of a damaged/deteriorated pipe that dictates the type of repair component to be applied is the external pipe surface condition. If the external surface is damaged to the extent that an elastomeric seal cannot provide sufficient sealing forces in the immediate vicinity of the damage, or in the relatively […] Read More

Factors influencing Rate of Corrosion

Introduction There are several factors influencing the rate of corrosion including diffusion, temperature, conductivity, type of ions, pH value and electrochemical potential. The rate of corrosion can be controlled or reduced by applying anti-corrosion coatings or corrosion protection techniques including composite repair compounds, metal repair putties and reinforcement wrap. We shall explore the different factors […] Read More

Corrosion Resistance through the Application of Anti-Corrosion Coatings

Introduction Corrosion is the surface disintegration of metals within specific environment. There are basically three factors by which corrosion can be classified – nature of the corrodent, mechanism of corrosion, and appearance of the corroded metal. The classification is based on the surface morphology and it must be noted that the forms of corrosion are […] Read More

5 Steps to Repair an Active Pipe Leaks

Introduction: Pipe erosion happens routinely and complete wall loss of pipe or through-crevice flaws are a general occasion at various spots. In the Oil & Gas and Offshore industry where burnable gases are accessible, it is imperative to modify these types of pipe leaks and pipe blemishes with cold curing repair. This is because hot […] Read More

10 Ways to Control Corrosion in Process Plants

Introduction Corrosion in industrial facilities and process plants is a costly mechanism. It could also have safety, environmental, and equipment reliability impacts and consequences. The top ten ways to control corrosion in process plants are as follows. 1. Corrosion of Buried Piping or Pipelines Apply impressed current cathodic protection and polarize the system to –850 […] Read More

Effective Use of Composite Wrapping and its Repair Techniques

Introduction The use of composite materials for the repair of carbon steel pipework has been originally designed in accordance with ASME/ANSI B31.3: Chemical Plant and Petroleum Refinery Piping. The use of composite materials for the repair of pipework covers the following circumstances: ■ external corrosion only (no leakage and structural integrity needs to be […] Read More

Different Type of Pipes Corrosion

Introduction The corrosion of steel piping and its related components is a continuous and virtually unstoppable process. The end product, rust, is the result of an electrochemical reaction through which the higher energy processed metal is slowly reverted back to its naturally occurring form – metal ore. Here’s a look at 11 different corrosion types […] Read More

Checking Surface Profile before Composite Repair of Pipeline

Introduction After the pipe surface has been prepared according to the required standards; the pipeline surface profile should be measured to ensure that the roughness meets requirement before commencing of composite repair of affected pipeline. Surface Profile Measurement of Prepared Surface The type and size of the abrasive used in blast […] Read More

Important Aspects of Surface Coating for Anti-Corrosion

Introduction Corrosion issues are clearly of economic costs and corrosion can lead to structural failures that have dramatic consequences for humans and the surrounding environment. Reports on the corrosion failures of metal structure, bridges, aircrafts, automobiles, buildings, and gas pipelines are not unusual. Both organic and inorganic coatings have been widely applied for the protection […] Read More

Surface Preparation for an Effective Pipe Leak Repair

Introduction: One of the single most important aspect in achieving successful pipe leak repair is the surface preparation of the affected pipe section to be repaired. For repairs to carbon steel pipe it is normally possible to achieve durable adhesion strength through means of mechanical abrasion being the only method of surface preparation. It is […] Read More

Effective Pipeline Reinforcement Techniques

Introduction Pipeline reinforcement services are performed to increase the pipe wall thickness of non-through hole pipe defects. The purpose is to increase the pipe wall thickness and therefore increase the pipe strength to meet its operating requirements. Especially so in the Oil & Gas and Offshore industry where hot work permits are not easily approved, […] Read More

How to Repair Pipe Leaks Without Hot Works.

Introduction Pipe corrosion happens regularly and complete wall loss of pipe or through-gap imperfections are a general event at numerous places. In the Oil & Gas and Offshore industry where combustible gasses are available, it is important to alter these sorts of pipe leaks and pipe imperfections with cold curing repair. This is […] Read More

How to Extend Service Life of Corroded Pipes by 20 Years?

Introduction If put unattended, inordinate outer and inner erosion, corrosion, disintegration, scraped spot, marks and breaks can all conceivably prompt catastrophes. These pipeline deformities when unattended can bring about costly and conceivably fatal results to resource proprietors and machineries administrators. Hence, these pipeline imperfections are obliged to suitable repairs or substitutions, contingent upon the seriousness […] Read More