Our Blog

Effective Repair Solutions for Pipe Joint Leaks

Here are a few stages to help you manage pipe blasts and pipe spills. This article manages impermanent pipe repair as opposed to supplanting it. The water supply is under pressure, usually around 40 to 60 psi. A patch on a leak obliges counter-pressure and a compressible material to help in adding embellishment to the […] Read More

Type of Anti-Corrosion Coating Failures

Introduction Anti-corrosion coatings do not last forever. They age, weaken and deteriorate and eventually their useful life ends. The most common cause for premature anti-corrosion coating failure is insufficient care during the mixing, application and curing processes. Poor application technique can typically cause problems such as improper thickness, pinholes, sags, mud-cracking, and holidays. Inadequate surface […] Read More

Effective Techniques to Repair Pipe Threading Leaks

Here are some steps to help you deal with pipe bursts and pipe leaks. This article deals with temporary pipe repair instead of replacing it. The water supply is under pressure, typically somewhere around 40 to 60 psi. A patch on a leak requires counter-pressure as well as a compressible material to help in molding […] Read More

Coating Inspection Requirements

Introduction Any individual required to carry out inspections is to be qualified to NACE Coating Inspector Level 2or an equivalent qualification. The appointed coating inspector shall carry out inspections and record the results of the inspection at the various stages and verify that these are in compliance with the standards. All deficiencies/ non-compliances found at […] Read More

How to Repair Pipe Weld Joints

Introduction Pipe weld joints are one of the weakest links within the piping system. Pipe leaks often occur around the weld joints due to various reasons. Some of the reasons include: 1) Lack of fusion 2) Corrosion at heat affected zone 3) Crack (due to heat stress, solidification, hydrogen-induced) 4) Porosity 5) Contamination 6) Inclusion […] Read More

Curing Conditions for Effective Anti-corrosion Coatings

Introduction There are a number of factors which must be considered when anti-corrosion coatings are applied. The major ones include: • Condition of the substrate • Temperature • Relative humidity • Weather conditions • Condensation • Ventilation • Ultraviolet light (UV) (1) Condition of the Substrate The surface must be clean and free from dirt, […] Read More

Tips on Repairing Underground Pipe Leaks

If a leak happens on an underground pipe after the meter from the water main, it looks like you will have to plan for the repair works to be carried out. This can be done with repair putty compounds. 1) Check and Confirm the Pipe Routing You may still have the old drawing of the pipe routing. […] Read More

Application Techniques for Anti-corrosion Coatings

Introduction The objective in applying anti-corrosion coatings is to provide a film which will give protection and/or decoration to the structure being applied. The variables which govern the success of any application and subsequent performance are: • Surface preparation • Film thickness of the paint system • Methods of application • Conditions during application Surface […] Read More

Effective Steps to Repair Copper Pipe Leaks

Introduction Copper Pipes have high mechanical quality; however the sensitive material is delicate and will weaken under high pressure. Leak will start to happen when the Copper Pipe system is subjected to considerable vibrations. Performing Copper Pipe leak repairs for little estimations can be viably completed after the underneath repair methods. Surface Preparation of Affected […] Read More

Edge and Weld Preparation for an Effective Anti-corrosion Coating

Introduction Experience has shown that edges and welds are generally the first areas to show corrosion and coating breakdown, particularly in ballast and cargo tanks. This is due to a number of inter-related processes including surface preparation, coating application, deflection, and shear and buckling stresses on the edges and welds and so on. The quality […] Read More

Common Causes of Flange Leaks and their Solutions

Introduction Common Causes of Flange Leakage By Vincent A. Carucci A previous article highlighted the primary causes of flange leakage. This article provides more information about these. • Uneven Bolt Stress. An incorrect boltup procedure or cramped working conditions near the flange can leave some bolts loose while others are overtightened and […] Read More

Surface preparations for an Effective Anti-corrosion Coating

Introduction Good surface preparation may be considered to be the most important part of the entire coating process in that the greatest percentage of coating failures can be traced directly to poor surface preparation. All paint or anti-corrosion coating systems will fail prematurely unless the surface has been properly prepared to receive the coating. If […] Read More

Temporary and Permanent Pipe Leak Repairs

Introduction Most pipe repair components have a design basis in accordance with internationally recognised codes or standards. However in most cases these codes or standards may not concern piping or pipelines, but concern pressure vessel type codes, such as ASME Section VIII: Pressure Vessel Code, or API 6H: Specification on End Closures, Connectors and Swivels. Pressure […] Read More

Anti-corrosion Coating Types and their Applications

Introduction This chapter covers the major types of coatings that are currently available for use and includes general information on the composition of coatings. It is intended to give basic information on coatings and is not a comprehensive guide to anti-corrosion coatings selection. The coating manufacturer is to be consulted if information on a specific […] Read More

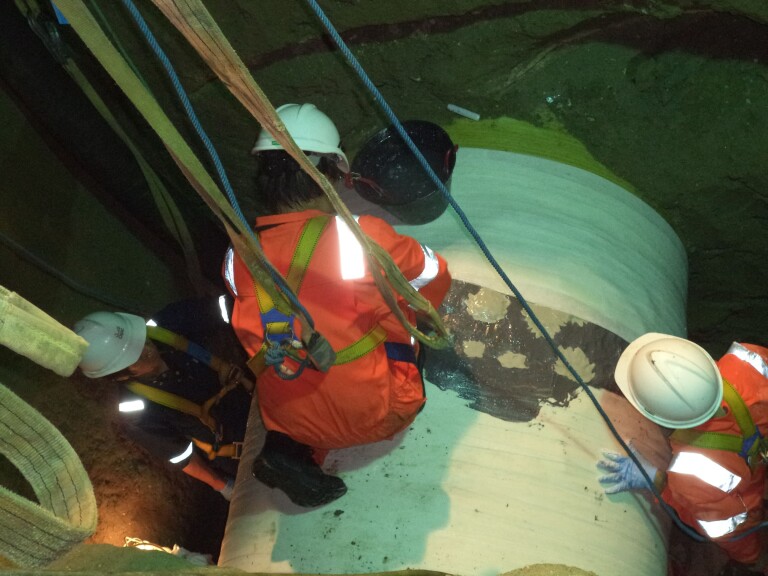

Pipe Leak Repair using Pipe Clamps

Introduction One of the main considerations that need to be taken into account when using a pipe repair clamps is the ability of the repair system to accommodate the pressure imposed axial loadings/stresses. The other main consideration is the pipe remaining wall thickness – if the mechanical strength of the pipe is sufficient to withstand […] Read More

Types Protections Provided by Anti-Corrosion Coatings

Introduction In corrosion prevention by anti-corrosion coatings, three main principles are employed in various combinations: 1) Create a barrier that keeps out charged ions and retards the penetration of water and oxygen. 2) Ensure contact between the steel and a less noble metal (e.g. zinc in the coating) provides cathodic protection of the steel utilizing […] Read More