WEAR & CORROSION RESISTANT COATING AND PUTTY

SEALXPERT WR204 WEAR RESISTANT COATING

FEATURES:

- Ceramic microsphere and silicon alloy filled two-component epoxy coating.

- Suitable for application on vertical surfaces.

- Coating has strong adhesion and excellent properties of wear and impact resistance.

APPLICATION:

- Designed to rebuild and pre-protect the machine worn by whirlpool, corrosion and cavitation erosion, water pump impellers, shell, induced-draft fan impeller etc.

TECHNICAL DATA:

| Colour | : | Dark Grey |

| Compressive Strength | : | 15,954 psi (1,122 kg/cm2) |

| Tensile Strength | : | 4,351 psi (306 kg/cm2) |

| Shear Strength | : | 2,176 psi (153kg/cm2) |

| Hardness | : | 90 Shore D |

| Temperature Range | : | -50 °C (-58 °F) to 121 °C (250 °F) |

| Mixture (A:B) | : | Weight – 4:1 / Volume – 4:1 |

| Pot Life | : | 40 min |

| Min. curing before function | : | 50% load – 10 hours 100% load – 24 hours |

| Coverage area (per set) | : | 378 cm2 at 6 mm thickness |

SEALXPERT WR206 WEAR SHIELD BRUSHABLE COATING (LARGE PARTICLES)

FEATURES:

- Alumina ceramic bead-filled epoxy system

- Outstanding abrasion resistance

- Designed for particulates larger than 3mm (1/8”)

- Resistant to wide range of chemicals (acids, bases, saturated salt solutions, oils, etc.)

- Service temperatures up to 150°C (302°F)

APPLICATION:

- Repair scrubbers, ash handling systems, pipe elbows, screens, and chutes

- Recontour chippers, bins, hoppers, bunkers, separators, diester tables

- Protect exhausters, chutes, launderers, housing fans, crushers, and breakers

TECHNICAL DATA:

| Colour | : | Grey |

| Compressive Strength | : | 11,000 psi (774 kg/cm2) |

| Tensile Strength | : | 4,210 psi (296 kg/cm2) |

| Shear Strength | : | 1,474 psi (104 kg/cm2) |

| Hardness | : | 87 Shore D |

| Temperature Range | : | Wet: 60°C (140°F) / Dry: 149 °C (300 °F) |

| Mixture (A:B) | : | Weight – 2:1 / Volume – 2:1 |

| Pot Life | : | 30 min |

| Coverage area (per set) | : | 5,000 cm2 at 6 mm thickness |

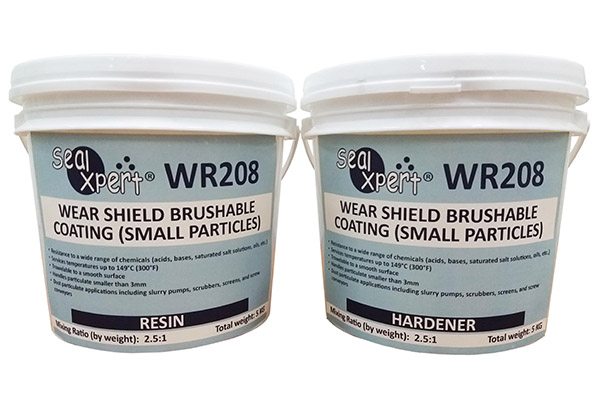

SEALXPERT WR208 WEAR SHIELD BRUSHABLE COATING (SMALL PARTICLES)

FEATURES:

- Micro-alumina ceramic bead-filled epoxy

- Outstanding abrasion resistance

- Designed for particulates smaller than 3mm (1/8”)

- Resistant to wide range of chemicals (acids, bases, saturated salt solutions, oils, etc.)

- Service temperatures up to 150°C (302°F)

APPLICATION:

- Dust particulate applications including slurry pumps, scrubbers, screens, and screw conveyors

TECHNICAL DATA:

| Colour | : | Grey |

| Compressive Strength | : | 11,000 psi (774 kg/cm2) |

| Tensile Strength | : | 4,300 psi (303 kg/cm2) |

| Shear Strength | : | 1,375 psi (97 kg/cm2) |

| Hardness | : | 87 Shore D |

| Temperature Range | : | Wet: 60°C (140°F) / Dry: 149 °C (300 °F) |

| Mixture (A:B) | : | Weight – 2:1 / Volume – 2:1 |

| Pot Life | : | 30 min |

| Coverage area (per set) | : | 5,000 cm2 at 6 mm thickness |

SEALXPERT WR209 CORROSION BRUSHABLE COATING

FEATURES:

- Excellent chemical resistance to acids, solvents, and alkalis

- Temperature resistance to 160°C (320°F)

- Applies easily with short-bristle brush or roller

- Low viscosity, self-leveling liquid

APPLICATION:

- Seal and protect new equipment exposed to erosion and corrosion

- Protect pump casings, impeller blades, gate valves, water boxes, and fan blades

- Rebuild heat exchangers, tube sheets, and other water circulating equipment

- Top coat for providing exceptionally smooth surface to repaired surfaces

TECHNICAL DATA:

| Colour | : | Brown |

| Compressive Strength | : | 15,000 psi (1,069 kg/cm2) |

| Tensile Strength | : | 4,351 psi (306 kg/cm2) |

| Shear Strength | : | 1,450 psi (102 kg/cm2) |

| Hardness | : | 85 Shore D |

| Temperature Range | : | Wet: 66°C (150°F) / Dry: 160 °C (320 °F) |

| Mixture (A:B) | : | Weight – 5.6:1 / Volume – 3.4:1 |

| Pot Life | : | 40 min |

| Coverage area (per set) | : | 7,200 cm2 at 0.375 mm thickness |

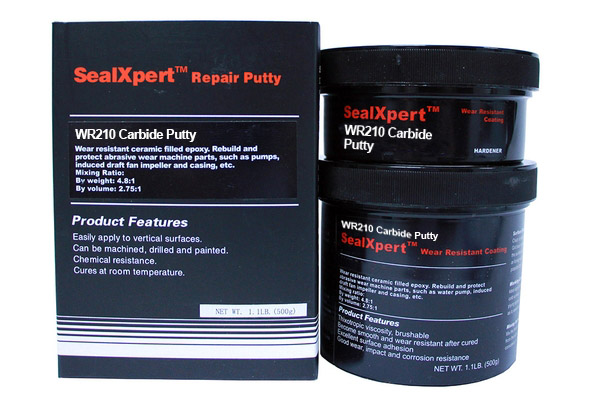

SEALXPERT WR210 CARBIDE PUTTY

FEATURES:

- Silicon carbide-filled epoxy putty

- Economical protection against wear and abrasion

- Designed for particulates smaller than 1.6mm (1/16”)

- Service temperatures up to 150°C (302°F)

APPLICATION:

- Particulate less than 1/16″: pipe elbows, pulverizers and slurry lines, cyclones and exhauster fans, chutes

TECHNICAL DATA:

| Colour | : | Grey |

| Compressive Strength | : | 8,160 psi (574 kg/cm2) |

| Tensile Strength | : | 2,640 psi (186 kg/cm2) |

| Shear Strength | : | 1,350 psi (95 kg/cm2) |

| Hardness | : | 85 Shore D |

| Temperature Range | : | Wet: 49°C (120°F) / Dry: 121 °C (250 °F) |

| Mixture (A:B) | : | Weight – 8:1 / Volume – 4:1 |

| Pot Life | : | 50 min |

| Coverage area (per set) | : | 378 cm2 at 6 mm thickness |

SEALXPERT WR211 CORROSION RESISTANT COATING

FEATURES:

- Composed of modified epoxy, wear resistant ceramic and crystal mineral powder

- Thixotropic viscosity, suitable for application on vertical surface

- Excellent resistance to strong alkali and acid

APPLICATION:

- Used for rebuilding and protecting metal material and concrete facilities against corrosion of acid/alkali solution

- Rebuilding and protective coating of various corroded pipeline, pump, valve, exchanger, etc.

TECHNICAL DATA:

| Colour | : | Dark Grey |

| Compressive Strength | : | 13,053 psi (918 kg/cm2) |

| Tensile Strength | : | 4,351 psi (306 kg/cm2) |

| Shear Strength | : | 1,450 psi (102 kg/cm2) |

| Hardness | : | 73 Shore D |

| Temperature Range | : | -50 °C (-58 °F) to 121 °C (250 °F) |

| Mixture (A:B) | : | Weight – 5:1 / Volume – 4:1 |

| Pot Life | : | 60 min |

| Coverage area (per set) | : | 378 cm2 at 6 mm thickness |