RESIN AND ACTIVATOR

WRAP SEAL PLUS RESIN

AND ACTIVATOR

FEATURES:

- Corrosion barrier and isolator

- High adhesion strength

- Excellent alkali and acid resistance

- Ease of application by using paint rollers and paint brush

- Applicable for pipes, tanks, and large surfaces

APPLICABLE MATERIAL:

- Galvanized steel

- Copper

- Stainless steel

- Carbon steel

- Concrete

- Polyethylene

- FRP/GRE

CHEMICAL RESISTANCE:

- MEK

- Diesel

- Ethylene glycol

- Ammonia

- Acetone

- Crude oil

- Toluene

- Ethyl alcohol

- Gasoline

- Sodium hydroxide

WORKING TIME:

10 minutes at 30 °C (86 °F)

CURING TIME:

2 hours at 30 °C (86 °F)

APPLICATION:

- Applied as corrosion coating on pipes, storage tanks, vessels, exhaust lines, bulkheads, machineries, joints, and large surfaces.

- Applied with Wrap Seal PLUS Uncoated Fiberglass Tape, Chopped Strand Mat or Surface Tissue for reinforcement, bonding and lamination

APPLICABLE INDUSTRIES:

Building & amp; Facilities

Building & amp; Facilities Electronics

Electronics Industrial Processing

Industrial Processing Irrigation

Irrigation Oil & amp; Gas

Oil & amp; Gas Chemical

Chemical Manufacturing Plants

Manufacturing Plants Marine

Marine Military

Military Offshore

Offshore Food Processing

Food Processing Petrochemical

Petrochemical Pharmaceutical

Pharmaceutical Power Generation

Power Generation Pulp & amp; Paper

Pulp & amp; Paper Wastewater

Wastewater Water Distribution

Water DistributionTECHNICAL DATA:

| Colour – Resin | : | Natural |

| – Activator | : | Straw colour |

| Viscosity | : | 20000 – 40000 cps at 21 °C (70 °F) |

| Specific gravity | : | 1.85 |

| Compressive strength | : | 24500 psi (1723 kg/cm2) |

| Tensile strength | : | 35000 psi (2461 kg/cm2) |

| Bond strength | : | 500 psi (35 kg/cm2) |

| Flexural strength | : | 42000 psi (2953 kg/cm2) |

| Flexural modulus | : | 1.6×106 psi (112491 kg/cm2) |

| Barcol hardness | : | 40 – 50 Shore D |

| Coverage area (per set) | : | 0.15 m2 at 3 mm thickness |

WRAP SEAL PLUS CORROSION REPAIR PROCEDURE:

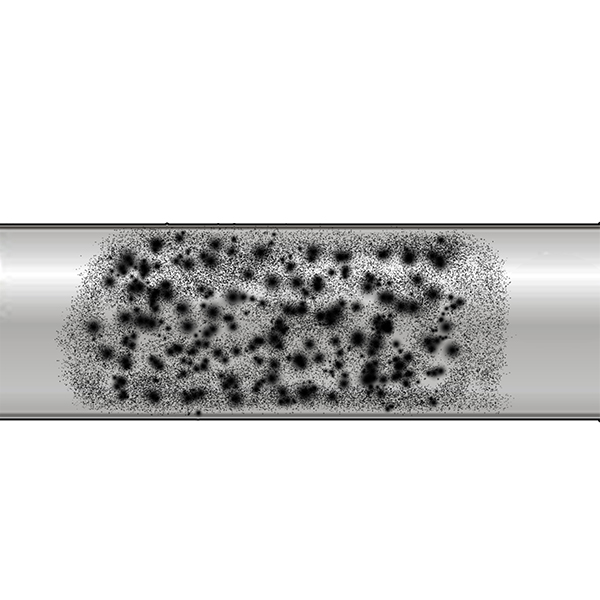

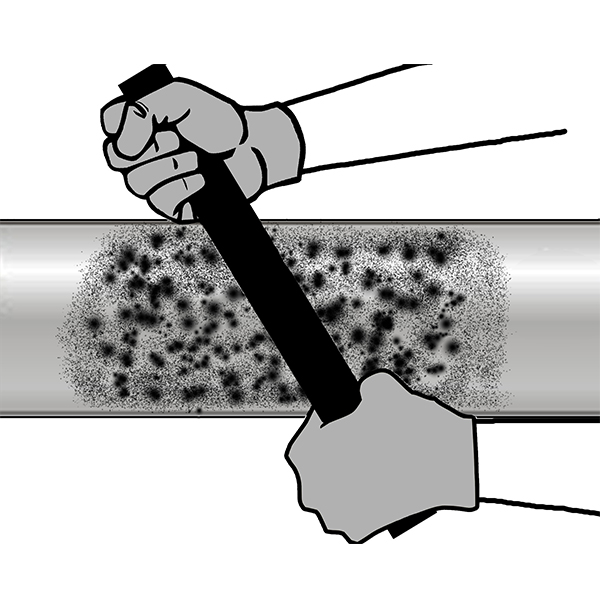

1

Corroded pipe surface

Corroded pipe surface

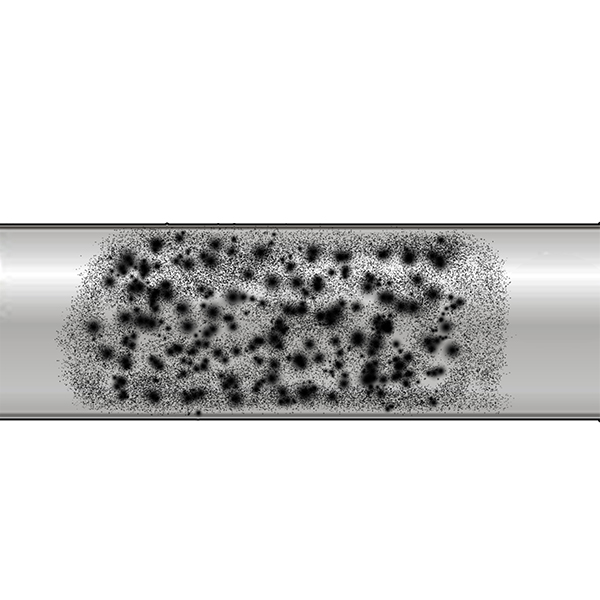

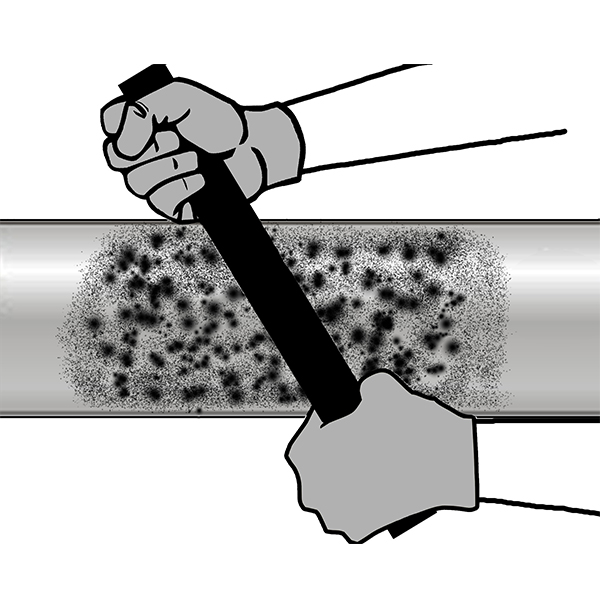

2

Roughen the area to be repaired

Roughen the area to be repaired

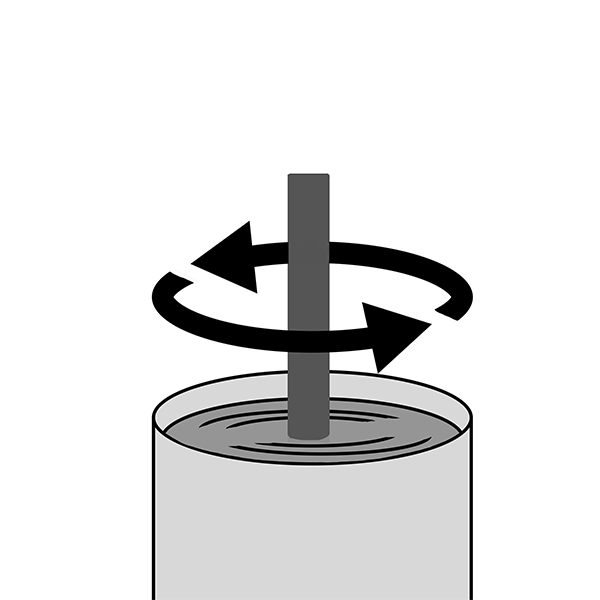

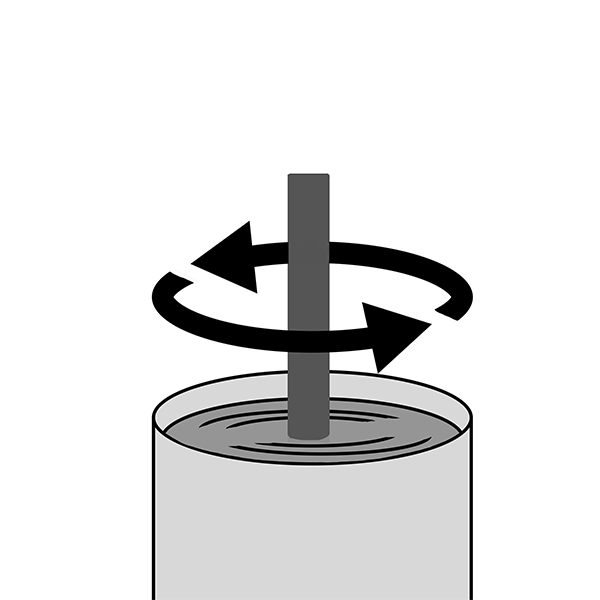

3

Mix and stir Wrap Seal PLUS Resin and Activator for at least 1 minute until well mixed

Mix and stir Wrap Seal PLUS Resin and Activator for at least 1 minute until well mixed

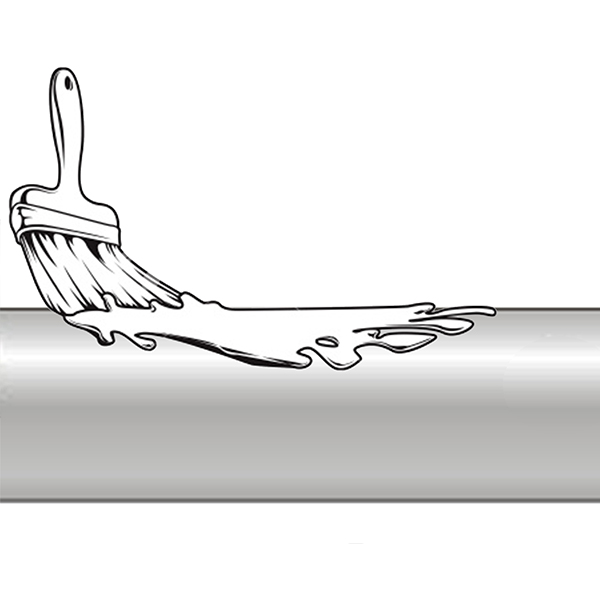

4

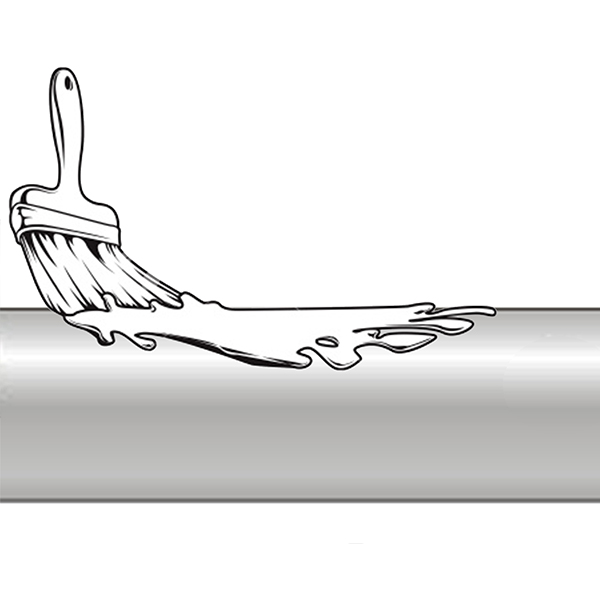

Apply two coats of activated resin evenly over the area to be repaired and allow to cure

Apply two coats of activated resin evenly over the area to be repaired and allow to cure

5a

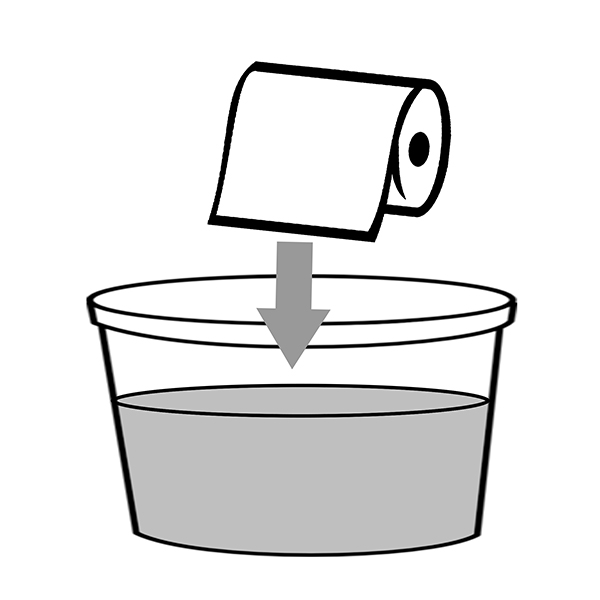

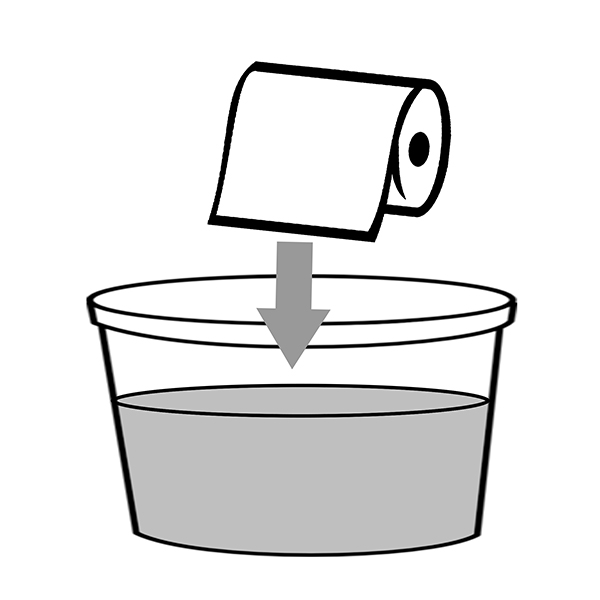

Immerse Wrap Seal PLUS Fiberglass Repair Tape into water

Immerse Wrap Seal PLUS Fiberglass Repair Tape into water

6a

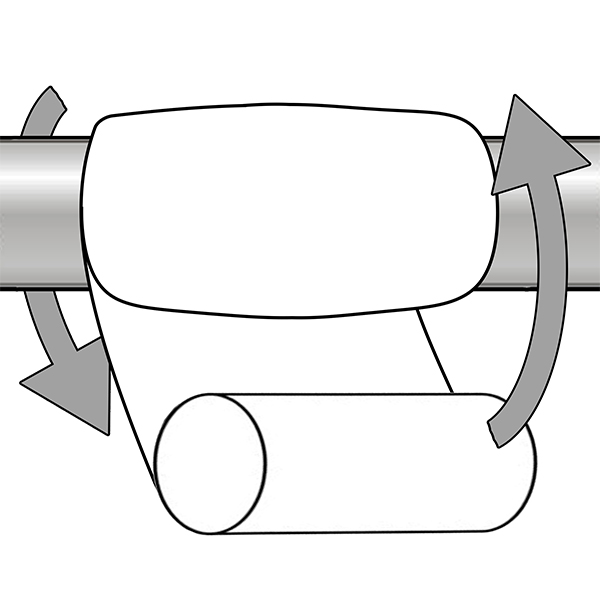

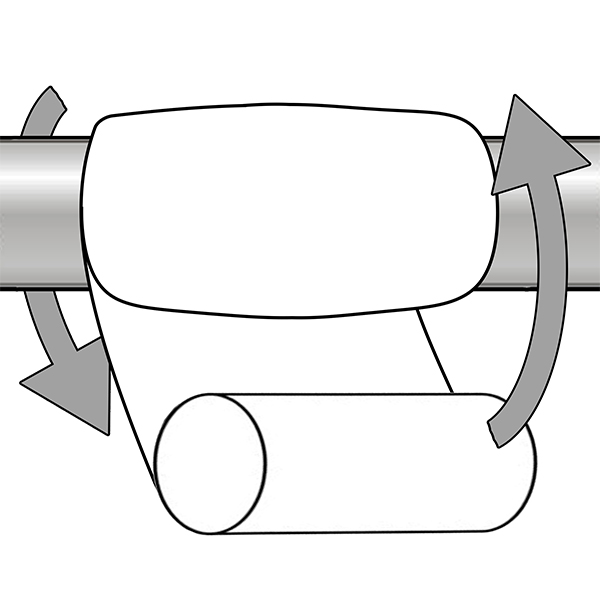

Wrap the fiberglass repair tape as tightly and evenly as possible, with at least 50% overlap over affected pipe length

Wrap the fiberglass repair tape as tightly and evenly as possible, with at least 50% overlap over affected pipe length

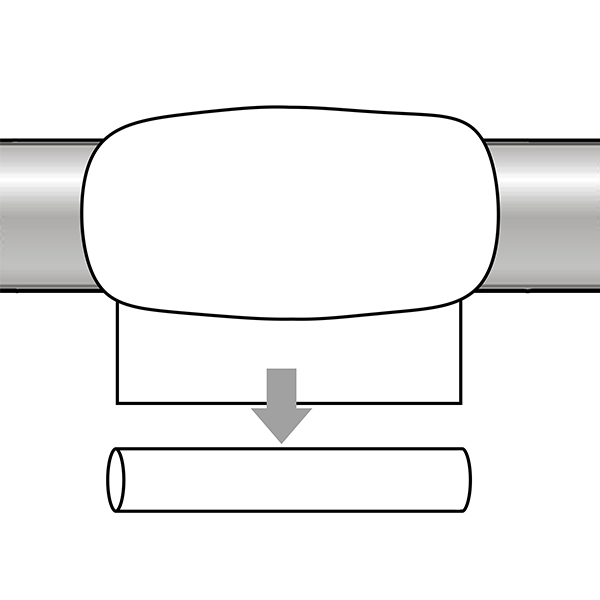

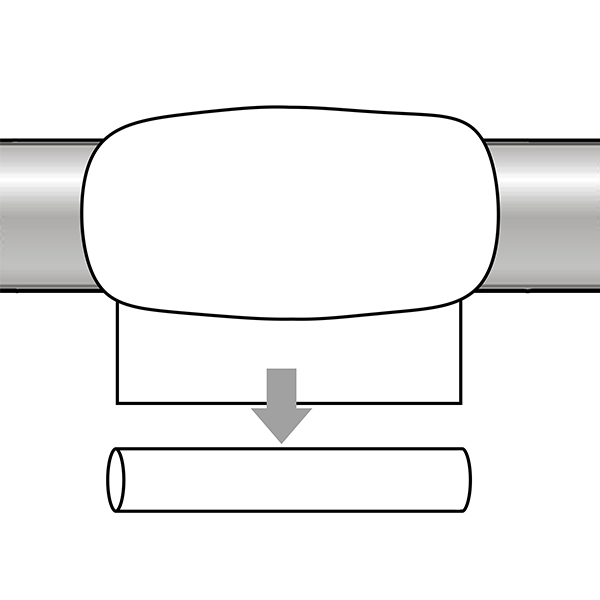

7a

Discard the plastic tube at the end of the roll

Discard the plastic tube at the end of the roll

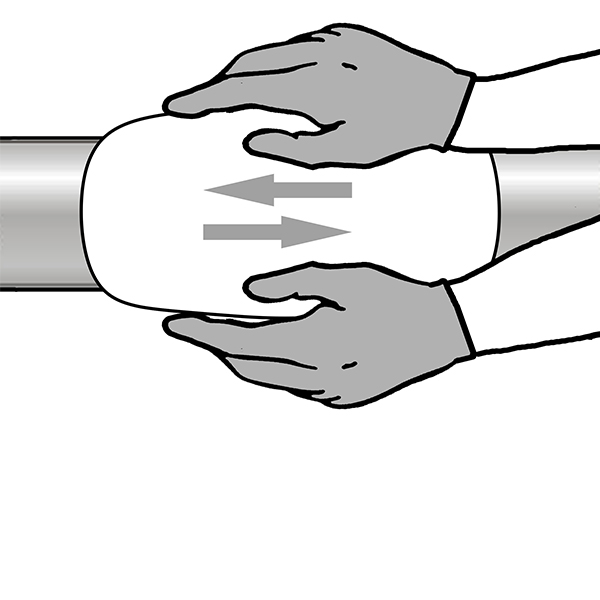

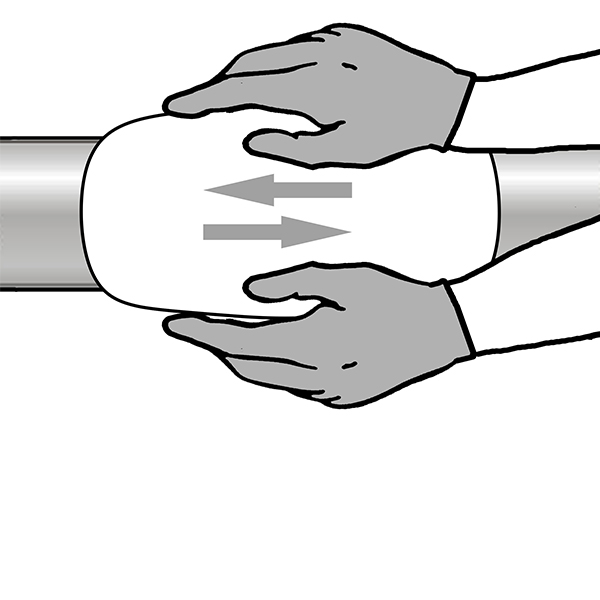

8a

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

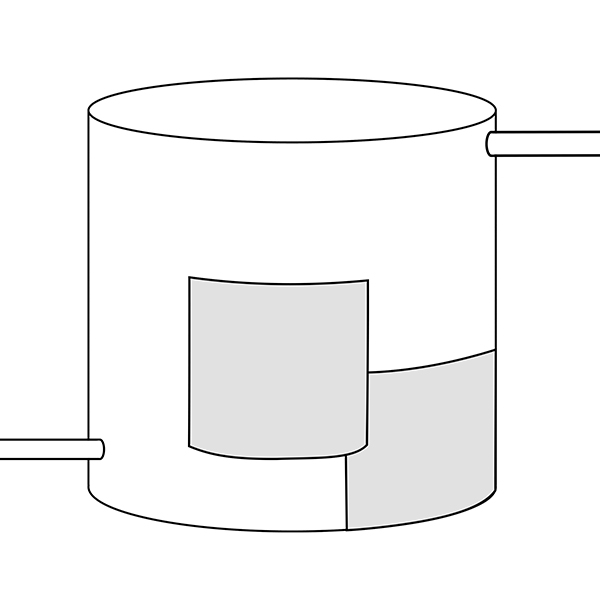

FLAT SURFACE/TANK

Apply Several layers of wrap Seal PLUS Surface Tissue or Wrap Seal Plus Chopped

Strand Mat onto the affected area.

Apply Several layers of wrap Seal PLUS Surface Tissue or Wrap Seal Plus Chopped

Strand Mat onto the affected area.

WRAP SEAL PLUS RESIN

AND ACTIVATOR

PACKAGE:

- 1 can of Wrap Seal PLUS Resin

- 1 bottle of Wrap Seal PLUS Activator

- Gross weight: 500 gm (1.1 lb)