LEAK REPAIR CLAMPS

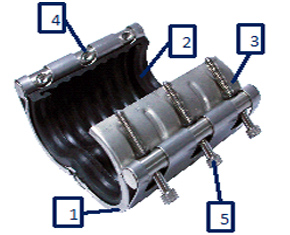

WRAP CLAMP WC1 LEAK REPAIR CLAMPS

FEATURES:

- Single side locking clamp

- Easy to handle, quick and simple to install

- No special tools or expertise required

- Stainless steel 304 / 316 material

CHEMICAL RESISTANCE:

- NBR: Water (drinking water, wastewater), gas, oil, gasoline and hydrocarbons, bases, slurries, fuels (petroleum, diesels, gasoline)

- Viton: Oil, water (drinking water, wastewater, steam), solvents (Acetone, toluene, MEK, ethyl alcohol), acids (hydrochloric acid, sulfuric acid), chemical (ethylene glycol, xylenes, ammonia), hydrocarbon, bases, slurries, fuels (petroleum, diesels, gasoline), gases (LNG, LPG), organic salts

APPLICATION:

- Applicable for pipeline pressure up to 363 psi (26 kg/cm2)

- Suitable for all pipe materials

- Acts as compensator for thermal expansion and dampens vibration

OPERATING TEMPERATURE:

- NBR: -20 °C (-4 °F) to 100 °C (212 °F)

- Viton: -95 °C (-139 °F) to 300 °C (572 °F)

SIZES AND TECHNICAL DATA:

| Model | O.D | O.D. Range mm | Length, L mm | Max Expansion Distance mm | MAX Pipe Distance (for Connection), G mm | Pressure Psi (kg/cm2) | Weight Kg | |

|---|---|---|---|---|---|---|---|---|

| Inch | mm | |||||||

| WC1-25A60 | 1 | 34 | 33-35 | 57 | 30 | 15 ± 10 | 363 (26) | 0.2 |

| WC1-32A60 | 1 ¼ | 42 | 42-44 | 57 | 30 | 15 ± 10 | 363 (26) | 0.35 |

| WC1-40A60 | 1 ½ | 48.6 | 47-49 | 60 | 30 | 15 ± 10 | 363 (26) | 0.35 |

| WC1-50A80 | 2 | 60.5 | 59-61 | 80 | 40 | 20 ± 15 | 363 (26) | 0.8 |

| WC1-65A140 | 2 ½ | 76.3 | 75-78 | 140 | 100 | 20 ± 15 | 363 (26) | 1.5 |

| WC1-80A200 | 3 | 89.1 | 88-91 | 203 | 150 | 25 ± 20 | 232 (16) | 3.1 |

| WC1-100A200 | 4 | 114 | 106-117 | 203 | 150 | 25 ± 20 | 232 (16) | 3.4 |

| WC1-125A200 | 5 | 140 | 138-142 | 204 | 150 | 30 ± 25 | 232 (16) | 4.7 |

| WC1-150A200 | 6 | 168 | 158-170 | 204 | 150 | 30 ± 25 | 232 (16) | 5.9 |

| WC1-200A255 | 8 | 219 | 216-222 | 255 | 150 | 30 ± 25 | 174 (12) | 12.2 |

| WC1-250A255 | 10 | 273 | 272-276 | 255 | 150 | 30 ± 25 | 174 (12) | 13.5 |

| WC1-300A255 | 12 | 325 | 324-328 | 255 | 150 | 30 ± 25 | 145 (10) | 16.3 |

| No | Components | Materials |

|---|---|---|

| 1 | Casing | SUS 304/316 |

| 2 | Rubber Sleeve | NBR |

| VITON | ||

| 3 | Slade Plate | SUS 304/316 |

| 4 | Threaded Rod | SUS 304 |

| 5 | Bolts | SUS 304 |

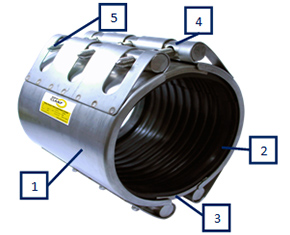

WRAP CLAMP WC2 LEAK REPAIR CLAMPS

FEATURES:

- Two side locking clamp

- Easy to handle, quick and simple to install

- No special tools or expertise required

- Stainless steel 304 / 316 material

CHEMICAL RESISTANCE:

- NBR: Water (drinking water, wastewater), gas, oil, gasoline and hydrocarbons, bases, slurries, fuels (petroleum, diesels, gasoline)

- Viton: Oil, water (drinking water, wastewater, steam), solvents (Acetone, toluene, MEK, ethyl alcohol), acids (hydrochloric acid, sulfuric acid), chemical (ethylene glycol, xylenes, ammonia), hydrocarbon, bases, slurries, fuels (petroleum, diesels, gasoline), gases (LNG, LPG), organic salts

APPLICATION:

- Applicable for pipeline pressure up to 174 psi (12 kg/cm2)

- Suitable for all pipe materials

- Acts as compensator for thermal expansion and dampens vibration

OPERATING TEMPERATURE:

- NBR: -20 °C (-4 °F) to 100 °C (212 °F)

- Viton: -95 °C (-139 °F) to 300 °C (572 °F)

SIZES AND TECHNICAL DATA:

| Model | O.D | O.D. Range mm | Length, L mm | Max Expansion Distance mm | MAX Pipe Distance (for Connection), G mm | Pressure Psi (kg/cm2) | Weight Kg | |

|---|---|---|---|---|---|---|---|---|

| Inch | mm | |||||||

| WC2-300A255 | 12 | 325 | 324-328 | 255 | 150 | 30 ± 25 | 145 (10) | 19.2 |

| WC2-350A255 | 14 | 377 | 375-379 | 255 | 150 | 30 ± 25 | 145 (10) | 22.0 |

| WC2-400A255 | 16 | 426 | 425-429 | 255 | 180 | 30 ± 25 | 145 (10) | 24.0 |

| WC2-450A255 | 18 | 480 | 476-480 | 255 | 180 | 30 ± 25 | 145 (10) | 25.8 |

| WC2-500A255 | 20 | 530 | 528-532 | 255 | 180 | 35 ± 25 | 116 (8) | 27.0 |

| WC2-550A255 | 22 | 559 | 557-560 | 255 | 180 | 35 ± 25 | 116 (8) | 28.2 |

| WC2-600A255 | 24 | 610 | 608-612 | 255 | 180 | 35 ± 25 | 116 (8) | 30.0 |

| WC2-650A255 | 26 | 660 | 658-663 | 255 | 180 | 35 ± 25 | 116 (8) | 32.0 |

| WC2-700A255 | 28 | 711 | 909-714 | 255 | 180 | 35 ± 25 | 101 (7) | 34.2 |

| WC2-750A255 | 30 | 762 | 759-765 | 255 | 180 | 35 ± 25 | 101 (7) | 36.6 |

| WC2-800A255 | 32 | 813 | 810-816 | 255 | 180 | 35 ± 25 | 101 (7) | 40.0 |

| WC2-850A255 | 34 | 864 | 861-867 | 255 | 180 | 35 ± 25 | 101 (7) | 42.2 |

| WC2-900A255 | 36 | 914 | 911-917 | 255 | 180 | 35 ± 25 | 101 (7) | 45.7 |

| WC2-950A255 | 38 | 965 | 962-968 | 255 | 180 | 35 ± 25 | 101 (7) | 48.5 |

| WC2-1000A255 | 40 | 1016 | 1013-1019 | 255 | 180 | 35 ± 25 | 101 (7) | 51.9 |

| WC2-1050A255 | 42 | 1067 | 1064-1070 | 255 | 180 | 35 ± 25 | 101 (7) | 55.4 |

| WC2-1100A255 | 44 | 1118 | 1115-1121 | 255 | 180 | 35 ± 25 | 101 (7) | 59.7 |

| WC2-1150A255 | 46 | 1168 | 1165-1171 | 255 | 180 | 35 ± 25 | 101 (7) | 64.1 |

| WC2-1200A255 | 48 | 1219 | 1216-1221 | 255 | 180 | 35 ± 25 | 101 (7) | 68.5 |

| No | Components | Materials |

|---|---|---|

| 1 | Casing | SUS 304/316 |

| 2 | Rubber Sleeve | NBR |

| VITON | ||

| 3 | Slade Plate | SUS 304/316 |

| 4 | Threaded Rod | SUS 304 |

| 5 | Bolts | SUS 304 |