UNCOATED FIBERGLASS TAPE / FIBER MAT

WRAP SEAL PLUS UNCOATED FIBERGLASS TAPE / GLASS CLOTH

FEATURES:

- Made by weaving yarn into cloth on a loom state

- Suitable for tube, tanks, pipes and structural products with high strength and high fiber content

- Not hazardous

APPLICATION:

- Specially designed for use in filament winding applications with epoxy resin systems

WRAP SEAL PLUS UNCOATED FIBERGLASS TAPE / GLASS CLOTH

PACKAGE:

- Wrap Seal PLUS Uncoated Fiberglass Tape

- 2” x 328’ (50 mm x 100 m)

- 4” x 328’ (100 mm x 100 m)

- Wrap Seal PLUS Glass Cloth

- 39” x 39”(1 m x 1 m)

WRAP SEAL PLUS CHOPPED STRAND MAT

FEATURES:

- Excellent conformability and handling

- Excellent weight uniformity

- Good mechanical properties

- Good laminate smoothness

- Non-hazardous

APPLICATION:

- Applied with Wrap Seal PLUS Resin and Activator to provide high tensile strength, impact, abrasion and corrosion resistance for large surfaces with low curvatures (storage tanks, vessels, etc.)

- Designed as surface rebuilding over large surfaces

TECHNICAL DATA:

| Appearance and odour | : | White / Off-white colored solid with odour |

| Density | : | 450 g/m2 |

WRAP SEAL PLUS SURFACE TISSUE

FEATURES:

- Excellent fiber distribution

- Good tear strength

- Good tensile strength

- Excellent weather-proofing

- Longer service life

- Non-hazardous

- Impose seepage resistance

APPLICATION:

- Applied with Wrap Seal PLUS Resin and Activator to provide high tensile strength, impact, abrasion,

and corrosion resistance for large surfaces (storage tanks, vessels, etc.) - Designed to be used as a surfacing tissue to provide a gel-coat/resin reinforcement and a smooth

resin-rich surface to the composite

TECHNICAL DATA:

| Appearance and odour | : | White / Off-white colored solid with odour |

| Glass type | : | C |

| Fiber diameter | : | 12.5μ ± 1 |

| Binder type | : | Styrene-acrylic |

| Thickness | : | 0.01″ (0.25 mm) |

WRAP SEAL PLUS CORROSION REPAIR PROCEDURE:

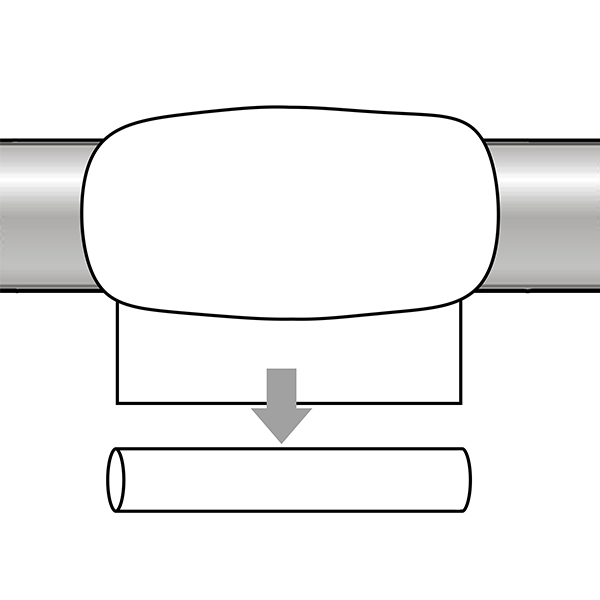

1

Corroded pipe surface

Corroded pipe surface

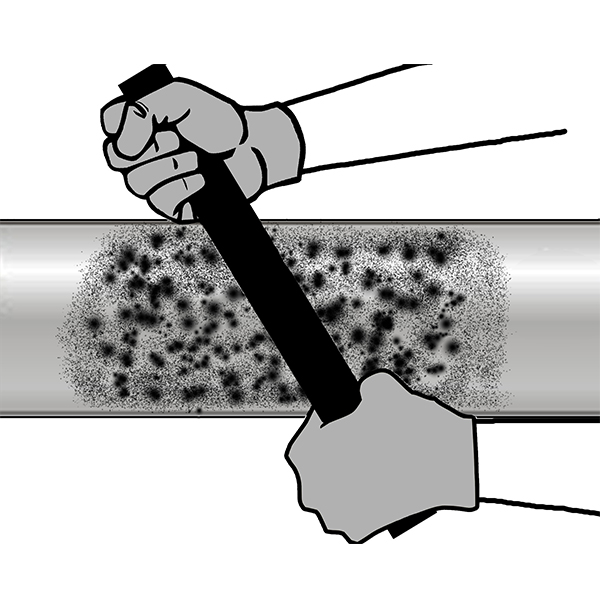

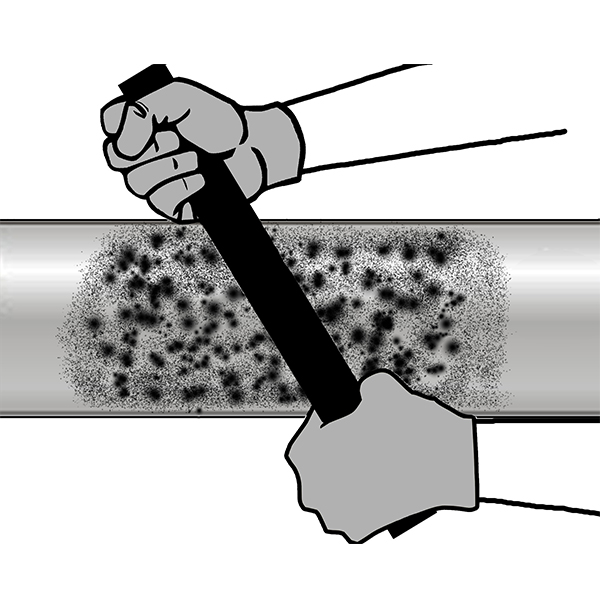

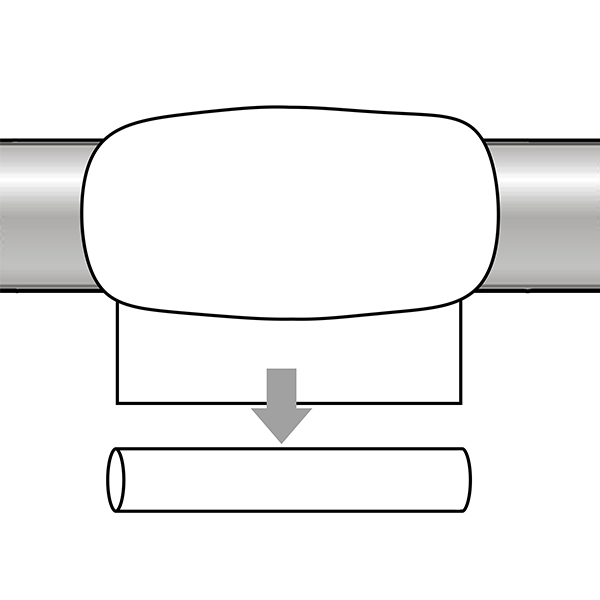

2

Roughen the area to be repaired

Roughen the area to be repaired

3

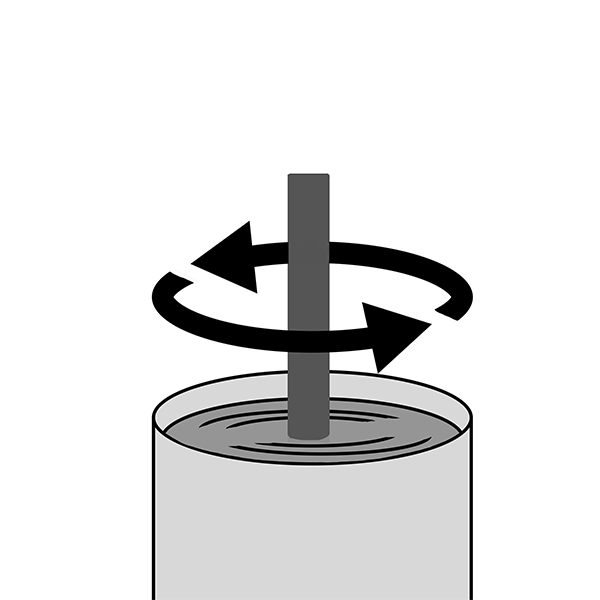

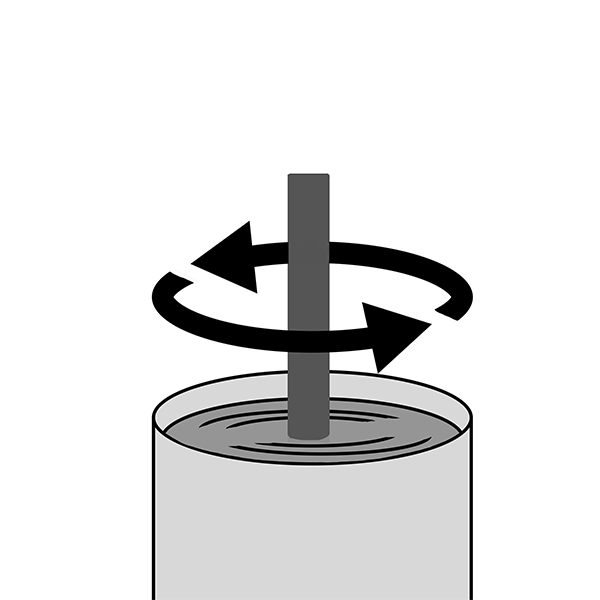

Mix and stir Wrap Seal PLUS Resin and Activator for at least 1 minute until well mixed

Mix and stir Wrap Seal PLUS Resin and Activator for at least 1 minute until well mixed

4

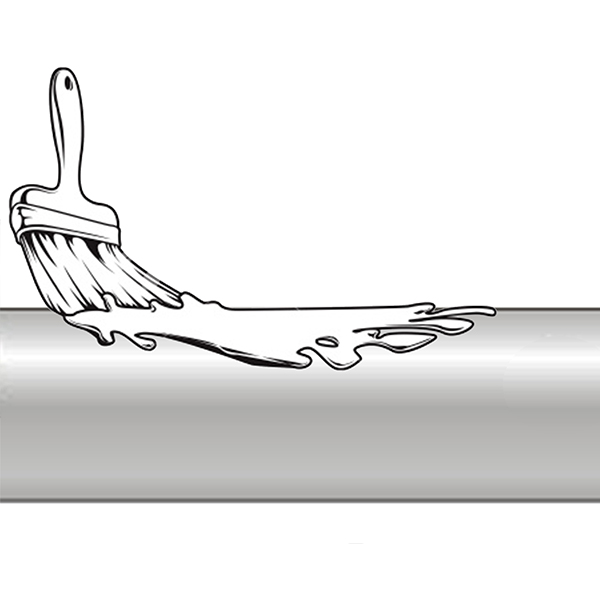

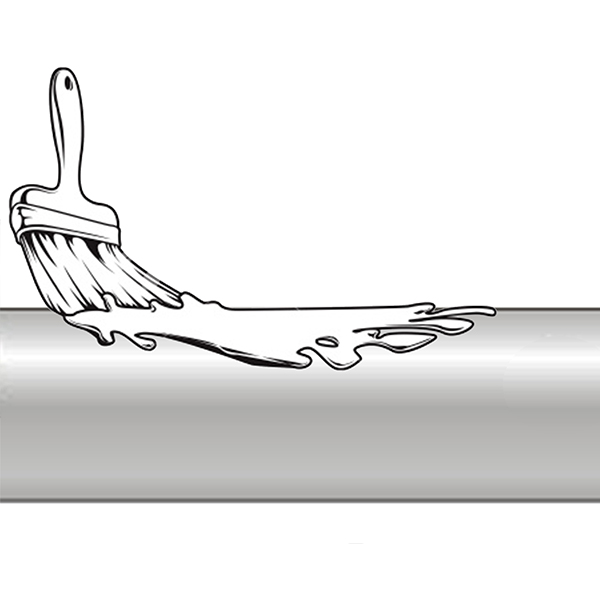

Apply two coats of activated resin evenly over the area to be repaired and allow to cure

Apply two coats of activated resin evenly over the area to be repaired and allow to cure

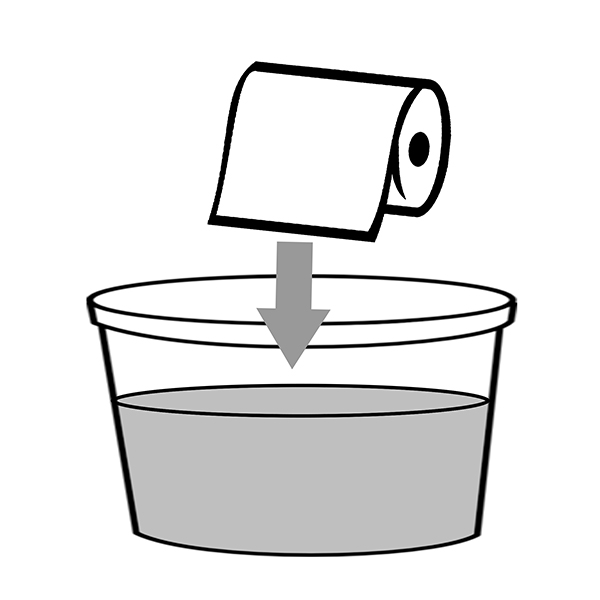

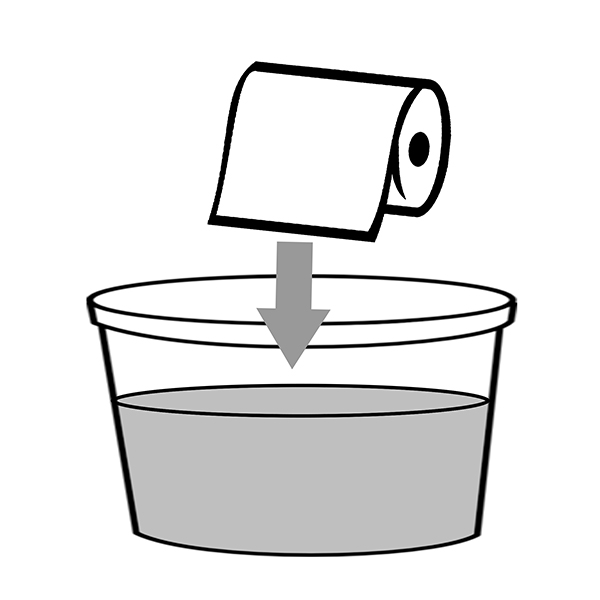

5a

Immerse Wrap Seal PLUS Fiberglass Repair Tape into water

Immerse Wrap Seal PLUS Fiberglass Repair Tape into water

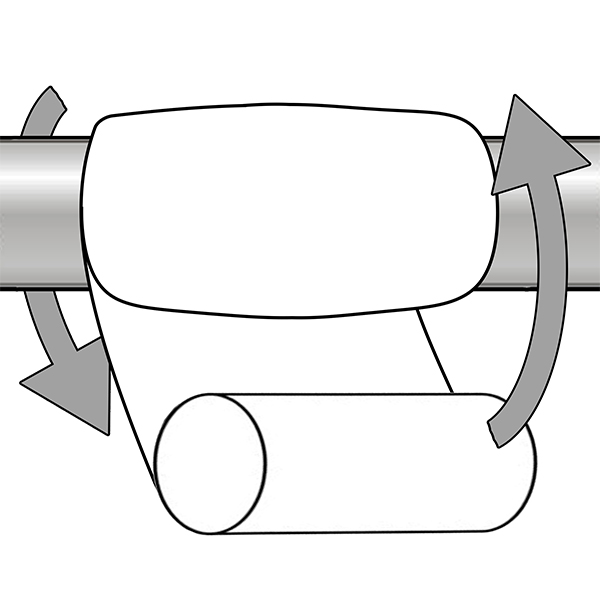

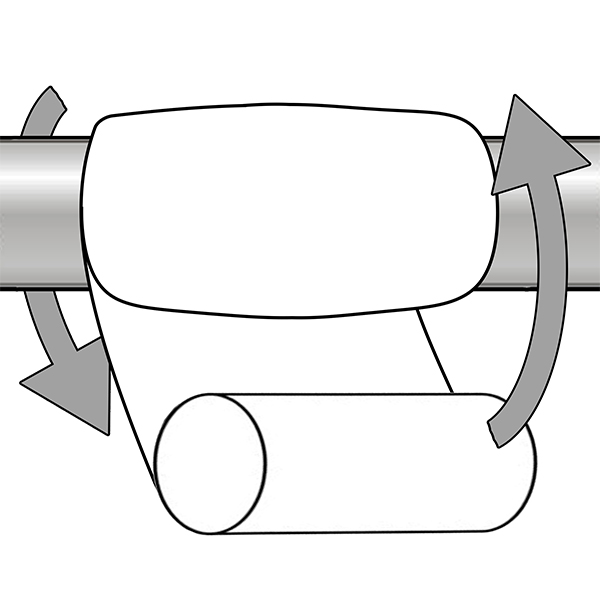

6a

Wrap the fiberglass repair tape as tightly and evenly as possible, with at least 50% overlap over affected pipe length

Wrap the fiberglass repair tape as tightly and evenly as possible, with at least 50% overlap over affected pipe length

7a

Discard the plastic tube at the end of the roll

Discard the plastic tube at the end of the roll

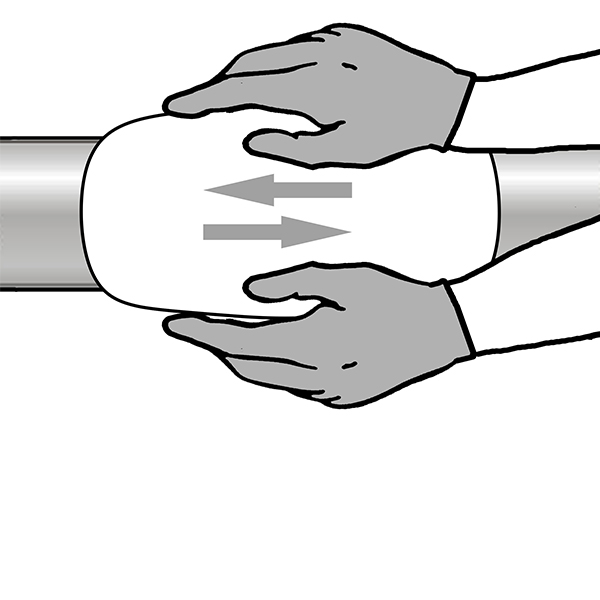

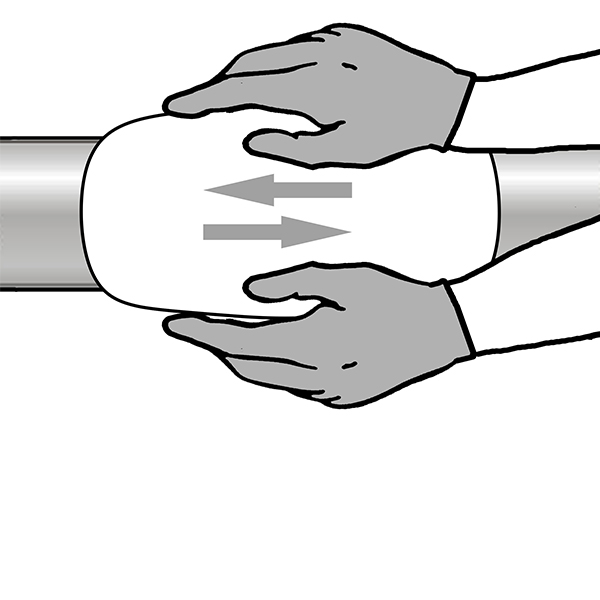

8a

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance

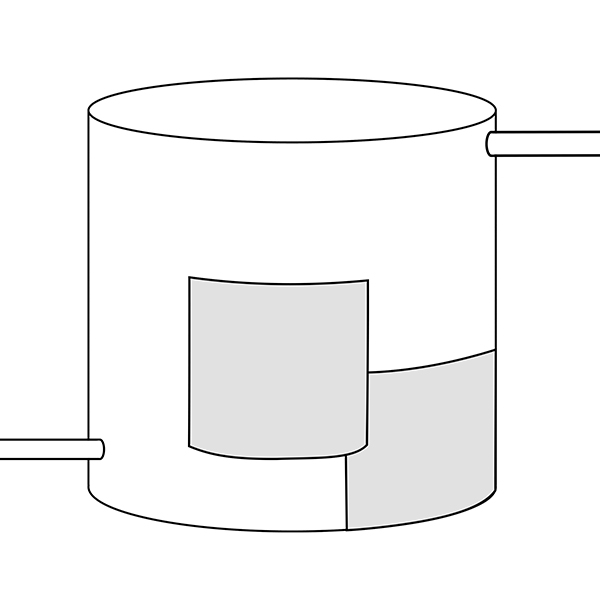

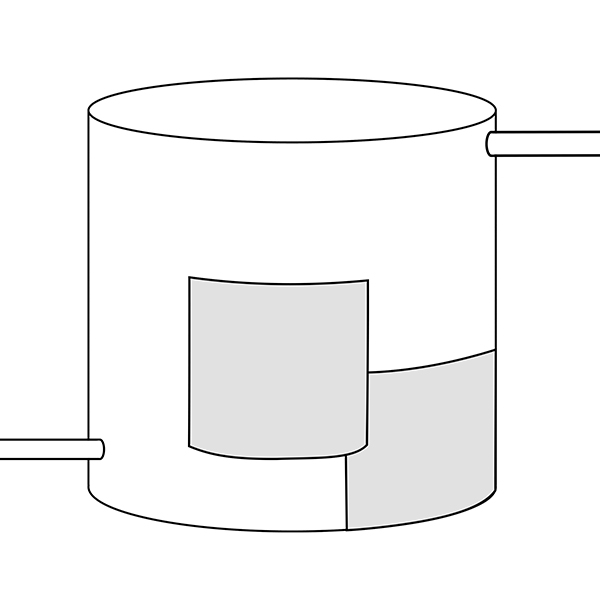

FLAT SURFACE/TANK

Apply Several layers of wrap Seal PLUS Surface Tissue or Wrap Seal Plus Chopped

Strand Mat onto the affected area.

Apply Several layers of wrap Seal PLUS Surface Tissue or Wrap Seal Plus Chopped

Strand Mat onto the affected area.